Brooks saddles - blocking and butchering!

Posted: Monday 21st September 2020

Having read Bernard Howard’s (‘Reminiscences’ – Memories of Cycling in the Fifties) mention of the ‘blocking’ of saddles on your site I thought I would add a little information to the subject.

I still have my 1960 Brooks B17F ‘French’ saddle supplied by Joe Whisker and I have asked lots of people from this era if they remember these saddles but no-one seems to recollect them. Maybe Joe only supplied a handful.

These saddles were specially made by Brooks for the Continental trade-team market which the teams then ‘butchered’ as required to suit their individual riders. The saddles had no holes in the top and no bag loops, they had standard size rivets and the leather was cut right back to the cantle-plate.

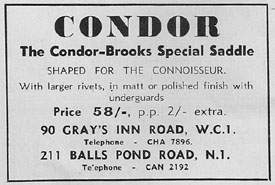

In 1961 Condor Cycles started to produce their own ‘Condor Brooks’ pre-shaped saddles at £2 18s. (see image below from Sporting Cyclist, February 1962) Also Pete Russel at his Velo Sport shop in Wandsworth Road (near Fred Dean’s) did a ‘Velo Sport’ pre-shaped saddle at £2 15s. I’m not sure if these were B17F or standard B17s before shaping.

In 1961 Condor Cycles started to produce their own ‘Condor Brooks’ pre-shaped saddles at £2 18s. (see image from Sporting Cyclist, February 1962) Also Pete Russel at his Velo Sport shop in Wandsworth Road (near Fred Dean’s) did a ‘Velo Sport’ pre-shaped saddle at £2 15s. I’m not sure if these were B17F or standard B17s before shaping.

I have spent a whole morning ‘butchering’ my B17F saddle – here’s how to do it:

Hold the saddle rail close to the cantle plate one side at a time. Using a ‘Thor’ style copper/rawhide mallet beat each corner down a bit. Then, on a concave block of wood, lay the saddle upside down and beat the rear-middle of the cantle plate to give a curve. Do this slowly, a bit at a time, and keep checking until you are happy with the shape. Take care that the saddle does not become lop-sided! Then trim off the leather level with the cantle plate and cut back the nose leather making sure you don’t cut too close to the rivet. Now use a coarse file to smooth off the edges. If you can get them you can fit the larger copper rivets – only replace one at a time though. Changing the nose rivet is very tricky so maybe settle for just the rear ones.

To soften and waterproof a saddle I always used olive oil. Turn the saddle upside down and run oil onto the underside turning the saddle to encourage the oil to run around, especially near the rivets. Let the saddle soak overnight. This is why these saddles were undrilled. The leather can be hammered with the rawhide mallet to soften it.

I have done this to my saddles since 1960 and no harm has come to the leather.

Many people will have their own ‘magic stuff’ to put on saddles, just the way they have recipies for embrocation. Olive oil and wintergreen was a favourite with riders but whether their girlfriends adored the pungent smell is another story!

‘Blocking’ is a term also used to restore distorted saddle tops. This can be done at home by soaking the saddle in warm water to get it really soft, then crumple up newspaper and stuff into the saddle to get the shape back. Be very careful and keep checking whilst the saddle is drying. Use a toestrap round the narrow part of the saddle to keep the shape intact while it is drying.

More details on the blocking of saddles in the 1940s and ‘50s (submitted by Alvin Smith, Paris Marque Enthusiast V-CC)

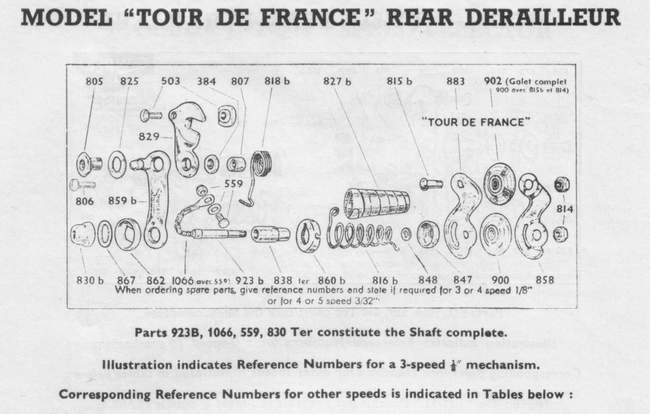

Ken Janes remembered a similar service to that described by John Spooner and Bernard Howard that was provided by Harry Rensch of Rensch and later PARIS Cycles to his team riders and which he may have offered to any paying customer. Ken was employed by the firm between summer 1947 and 1948 and recalled that when not supervising others Harry could be found busy reshaping Brooks saddles. This was because the standard Brooks B17 had too much of a step from the peak to the cantle to allow a rider to slip backwards off it when beginning to ‘honk’ or dance on the pedals, particularly in comparison with the French Ideale saddle which had a smoother transition. Harry’s solution involved drilling out the rivets holding the leather to the cantle plate and saddle nose. Once the leather was removed, he would detach the original cantle plate with its wide sharply radiused ends and it in its place weld to the wire frame another cantle plate of his own manufacture. (see image above)

This one had a more gentle, sweeping radius –the aim being a more comfortable shape for the rider. The butt leather would then be stretched over the assembly (using specially made hook nosed pliers made by Ted Henderson) and then re-riveted. (see image above)

Many riders favoured this design over that of the original Brooks pattern. The illustrations show just such a blocked saddle found on a very early PARIS Tour de France.

Text and illustration extracted from “Working with PARIS CYCLES –Conversations with Ken Janes” by AJE Smith The Boneshaker 175 2007

Posted: Monday 21st September 2020

Contents

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.