The inch-pitch block chain in 20th century track racing

Posted: Tuesday 18th August 2020

‘The bicycle chain is a complicated though often neglected item’. (R. Watson & M. Gray, The Penguin Book of the Bicycle, 1978).

‘The bicycle’s chain is a very clever and effective transmission element, which deserves a lot more care than it usually gets’. (Rob Van der Plas, The Bicycle Repair Book, 1986)

‘The block chain differs considerably from the roller type it is composed of three pieces: two plates, a pin in hard steel and the blocks. The plates are similar to those of the roller chain; however, inside them is a small steel block 3mm thick. The whole is held by small pins riveted at the ends the block chain is used for track races being rigid (it) allows greater performance both in the “jumps” and in the initial start the block chain (Humber gauge) is very little used nowadays.’

(Cycling CONI, FIAC, Rome 1972)

The pure track racing machine is universally admired for its functional simplicity. The single fixed gear system minus brakes and attendant cables combine to give it an unmistakeable symmetry. Of the numerous exquisitely crafted steel track machines on display in Classic Lightweights’ ‘Readers Bikes’ my own personal favourite is the Jack Sibbit exhibited by Gary Higgitt (see image below). But others also attract the eye: a 1937 Bates, two Carlton Flyers, a 1959 Ephgrave No.1, a 1950s Hobbs of Barbican and, of course, the Harris/Plattner Raleigh. Add to these the track irons by Cinelli, Condor, Coppi, JRJ–Bob Jackson, Mercian and Pollard on CL and any track cycling enthusiast can enjoy a gourmet feast. (See Appendix A for further details)

A notable feature of all these classic steel track machines is their seemingly timeless quality. They all bear a close family resemblance to one another with few obvious clues as to their exact construction dates. However, their minimalist profiles differ starkly from that of the typical modern track machine. With its disc wheels, aerodynamically sculpted frame and streamlined components all in stealth bomber black carbon, the modern track bike is decidedly industrial–looking. Clearly, the technology of the track machine changed dramatically somewhere in the late 20th century.

This revolution’s origins are directly traceable to Francesco Moser’s breaking of the 50 kilometre barrier for the iconic unpaced hour record. In 1984 Moser set a record distance of 51.151 km in Mexico City on a radically aerodynamic machine with solid ‘lenticular’ disc wheels. In so doing he eclipsed Eddy Merckx’s definitive 1972 hour record of 49.431 km set on a conventional (at least to outward appearances) track machine. Moser’s dramatic breaking of the Merckx hour record opened the technological floodgates for the development of aerodynamic machines. During the 1990s, track riders led the way in this regard with successful hour record machines like Obree’s ‘Old Faithful’ and Boardman’s Lotus in the vanguard.

However, it would be a mistake to assume that the post–1980s aerodynamic revolution was the only one to have occurred in the technology of track racing machines in the course of the 20th century. Another significant change took place in the early 1960s but because it was far less visible it remained a ‘quiet revolution’. Today it is one which is all but forgotten. Essentially, it involved the abandonment of the inch pitch block chain transmission system as the trackman’s drive train of choice in favour of the ubiquitous bushed half inch pitch roller chain system. This might now seem to have been of little significance but at the time its effects were dramatic. It changed how track riders thought and talked about gearing, profoundly altered their gearing choices and, as a direct result, subtly influenced the design of track machines. However, to fully grasp the extent of this change it is necessary to first appreciate the distinctive nature of the single fixed inch pitch block chain transmission system and how it permeated the craft of track racing for much of the 20th century.

On the block chain, unlike the roller chain, every second link is solid. As a result and in contrast to the roller chain system, the block chain’s matching rear sprocket and front chain ring have every second tooth missing. According to its proponents, the solid links together with the absence of rollers simultaneously increase the chain’s lateral rigidity, directness and responsiveness to pedalling pressure. In high speed track racing on a single fixed gear the block chain’s advantages were claimed to be that it:

- Maximises power transmission;

- Minimises the chances of chain derailment or breakage; and

- Responds instantly to pedalling pressure.

These are all qualities much prized especially by match sprinters since they often ‘jump’ from a low speed to maximum velocity. But they also appealed to explosive short distance specialists and those riding in the 1,000m. TT. The violent efforts involved in all of these events put enormous strain on the transmission. During the classic era these purported advantages of the block chain system were thus considered ideally suited to track racing. This was despite its being inherently noisier and less smooth in operation than the roller chain.

The origins of block chain transmission lie in the late 19th century and the advent of the ‘safety’ bicycle. Its initial application in cycling is traceable to the British Humber cycle company. However, quite when it became the norm in track racing is unclear although this appears to have occurred early on. Certainly by the 1920s the block chain had become the transmission system of choice in track racing and in match sprinting in particular. Thus, for instance, by the late 1920s the Williams C34 chainset was being offered in an inch pitch version and in the 1930s it became an option for the Williams B100 as well. Both continued to be produced for decades indicating that a substantial demand then existed for this system. This was at a time when track racing on both outdoor and indoor velodromes was firmly ensconced as a popular spectator sport internationally.

Technically the term ‘inch pitch’ refers to the distance between the central points of successive teeth on the cogs and chain wheels of this gearing system. It thus determines the commensurate length of the alternating links and ‘blocks’ of the matching chain. As applied in cycling, the standard internal width of the open links of the block chain was 3/16”. This differed from the half–inch pitch roller chain transmission system on which the links measured â…›” internally but subsequently diversified, becoming 3/32” for derailleur gears. Clearly, therefore, the block chain and roller chain transmission systems as applied to bicycles were totally incompatible. Tangibly, a switch from one to the other required a complete change of the chain, the rear cog and the chain ring. Less visible, however, were other fundamental differences that its use brought to the practise of track racing.

Of the machines on the CL website fitted with block chains, the Sibbit transmission spec is listed as 21T chain wheel x 7T cog, on the Fossett/Peacock Carlton Flyer 27 x 7, on the other Carlton 23 x 7 (with a 9T spare sprocket) and on the Ephgrave 27 x 7. To modern cyclists familiar only with half inch pitch chains these numbers will make little sense. However, doing the maths using the British formula reveals these machines to have gear ratios of 81.0”, 104.2”, 88.7” (69.0”) and 104.2”, respectively. What this points to is that classic trackies who used the block chain system were obliged to think and talk about gearing in a distinctive way. In short, the gearing lingua franca of these trackmen differed from that of other cyclists and served to set them apart. But much more than an alternative ‘gearing language’ was involved. The block chain system impacted on actual gearing options and gearing choices because of the practicalities involved in using it. (See Appendix B for an inch pitch block chain gear chart)

This is well illustrated by an account in the autobiography of the legendary post–WWII British trackman, Tommy Godwin. In this he writes of the British track team which raced in South Africa early in 1948. He describes the team’s activities on the eve of an international track omnium against a South African team in the city of Kimberley, celebrated as a diamond mining centre. Situated at high altitude, Kimberley had a large (c.550 yards) outdoor track at the De Beers stadium with a fast cement surface. (Legend has it that it also contained local diamond–bearing sand). Godwin writes about the British team in Kimberley as follows:

‘Prior to the meeting we became keen on making record attempts. Lew Pond achieved 29 seconds for the standing start quarter mile (South African Record) … On Friday we all agreed to go for the quarter–mile flying start TT. (Ian) Scott went first with 25.3 seconds, then (Alan) Bannister with 24.7. Pond next equalled this time and finally Godwin in only his second attempt at the flying quarter achieved 24.5, beating the top two. Bannister decided to go again with a gear raised from 92” to 96” and equalled Godwin. These times beat W.J. Bailey’s record of 24.8 seconds, set up at Herne Hill in the early 1900’s.* ‘(T. Godwin, The Tommy Godwin Story, p.79) *Bill Bailey was world amateur sprint champion, 1909–1911 and 1913.

Alan Bannister was an accomplished match sprinter who went on to partner Reg Harris on the tandem at the 1948 London Olympics at which they won the silver medal. To anyone familiar with the block chain system, Bannister’s decision to raise his gear by four inches from 92” to 96” would come as no surprise. What Bannister must have done was to change from 24 x 7 (92.6”) to 25 x 7 (96.4”). In other words, he changed his chain ring for a larger one. However, the increase of one tooth in the inch pitch system is equal to an increase of two teeth in the half–inch pitch roller chain system. What this points to is that, relative to the half inch pitch chain, the inch pitch system restricted gearing options. This obliged the rider to think very carefully about gear choices and to plot the most appropriate gear within the practicalities of the parameters set by the block chain system. Since a change in the size of the chain ring has less of an effect on the overall gear ratio than does a change in the rear sprocket size, it follows that trackmen in the classic era were more likely to change the sizes of their chain rings than of their rear sprockets. But this in turn had further technical implications.

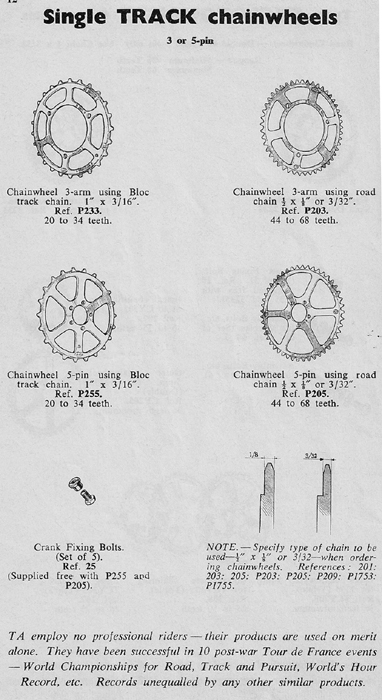

In the first instance, the classic track rider thus needed a block chainset with detachable rings. Furthermore, the bolts attaching the ring to the right hand crank needed to be easily accessible. In addition, once removed from the crank ideally the ring should be able to clear the attached pedal/toeclip assembly. Various solutions were developed by chain wheel manufacturers to resolve these problems, the three arm crank being one. But, since trackies and especially sprinters demanded very rigid chainwheels they tended to prefer five pin cranks. However, these were often characterised by limited access to the fixing bolts. An interesting solution to this problem is evident in the design of the Harris/Plattner Raleigh seen in the image below.

Under its bottom bracket is a chiselled slot which allows easy access to the five pin fixing bolts attaching the ring to the crank. But the technical implications of the block chain system did not end there.

Since a difference of one tooth on the block chain system was equivalent to two teeth on the roller chain, the tension of the block chain invariably needed careful adjustment when gear changes were made. To effect this the position of the rear wheel hub axle in the rear track ends had to be changed substantially. To meet the need for this and maximise the possible options of chainwheel and rear cog combinations with the block chain system, the best frame builders did two things: they incorporated longer track ends into their rear triangles and they slackened the seat angle. These two combined to allow for wider adjustment of the position of the rear wheel along the horizontal plane. Both of these design features are evident on the CL website’s Sibbit and also on the other classic machines on display there. Only on the pure match sprint Harris/Plattner Raleigh (see image below) are there tighter limits to the rear triangle and in the seat tube angle which reflect its specialised purpose.

Why then the sudden demise of the inch pitch block chain transmission system in the early 1960s after it had been in vogue amongst trackies for decades? Rather than having a single cause, a combination of factors – some historical, others technological – suggest themselves. These include:

- The general decline in popularity of track racing in the 1960s and a resulting decline in the availability of specialist track equipment.

- A demand for both a wider and more nuanced choice of gears for trackwork.

- A fashion for track machines with tighter clearances and shorter wheelbases (the CL 1970 Coppi’s wheelbase is 37½”).

- The retirement from racing of the legendary old–style traditionalist sprint superstars –Harris, Van Vliet and Plattner – all of whom relied on block chains.

- The popularising of individual and team pursuit events requiring smooth pedalling rather than explosive efforts.

- Improvements in half inch pitch transmission technology both in the â…›” steel roller chain and in precision alloy chain sets (although Campagnolo continued to produce alloy inch pitch block chainsets into the early 1970s).

The influential examples of star 1950s roadmen–turned–trackmen using roller chains on the track, as Reg Harris once explained:

‘Hugo Koblet was one of the world’s greatest all–rounders …Koblet took pursuiting in the same stride that won him the Tour de France and innumerable road classics … A big, tall, blond man Koblet used the same size and weight of frame for pursuiting as he did on the road … he also turned, for pursuiting, I remember, from the 3/16 in. block to a ½ x 3/32 in. roller chain … to take advantage of the supposed better “roll” of roller transmission under a non–explosive effort, and to obtain the “in between” gear ratios … Generally he used a 91 in. gear with 6¾ in. cranks … ideal for such a beautiful pedaller’.

(Reg Harris, ‘The world’s Great Pursuiters’, Cycling, July 30, 1958, pp.84–85)

Whatever the case, the reality is that from the early 1960s onwards the ½” x â…›” (or sometimes even the ½” x 3/32”) roller chain system rapidly became established as the norm for track racing, displacing the block chain. This situation has persisted ever since despite a brief flirtation by Shimano with a ‘compact’ 10mm pitch roller chain system in the mid–1970s. This was showcased by the Australian 1975 world professional match sprint champion John Nicholson, but it never caught on. (Nicholson was also noted for having his shoes bolted to his pedals – another innovation with few followers!).

Viewed from our present vantage point early in the 21st century, the trackman of old’s inch pitch transmission system may well be but a distant memory. However, its influence on both the craft of 20th century track racing and the subtleties of classic track machine design were such as to merit it being both respected and remembered. Fortunately for us, the exquisite track machines in Classic Lightweights’ Readers Bikes make this possible.

Acknowledgements

This article had its origins in a highly informative conversation I had with legendary South African trackman, Tommy Shardelow. Tommy won a silver medal at the 1952 Helsinki Olympics in the tandem sprint with partner Ray Robinson. (The 1952 Olympic tandem gold medallists were the Australian pairing of Mockridge and Cox). Tommy won five South African match sprint titles in the early 1950s, was a friend and rival of Mario Ghella, and raced against the 1952 British touring team in SA, beating the team’s sprinter Lloyd Binch. In 1954 he was match sprint bronze medallist at the Commonwealth Games. He raced on many European tracks including the Vigorelli during the 1950s. He later coached black African track cyclists on SA gold mines and served as a team manager on the Rapport Toer in the 1970s. He now lives in retirement in Cape Town.

Appendix A: Selected classic track machines from CL’s ‘Readers Bikes.

| Make | Date | Owner and provenance |

| Bates* | 1937 | Bill Corbett [reputedly ridden by ‘Torchy’ Peden in 1937 London 6 day] |

| Carlton Flyer* | Pre-1954 | Ray Fossett [originally Cyril Peacock] |

| Carlton Flyer* | 1960 | Bob Johnson |

| Cinelli | 1971 | David Rapley |

| Condor | 1953 | John Gray |

| Coppi | 1970 | Hakan Bilimlier |

| Ephgrave* | 1959 | Mario Romeo |

| Flying Gate | 1981 | Bill Corbett |

| Hobbs of Barbican | c1950 | |

| JRJ/BobJackson | 1952 | Justin Cotton |

| Mercian | 1976 | Peter Underwood |

| Pollard | 1959 | Bill Barbett |

| Raleigh* | 1949/52 | David Rapley (Reg Harris special ridden by Oscar Plattner) |

| Sibbitt* | c1950 | Gary Hibbitt |

* equipped with block chain

Appendix B: Inch pitch block chain gear chart.

| Rear Cog (No. of teeth) | Chainwheel (No. of teeth) | Gear in inches |

| 7 | 27 | 104.2 |

| 26 | 100.3* | |

| 25 | 96.4* | |

| 24 | 92.6* | |

| 23 | 88.7* | |

| 22 | 84.9 | |

| 21 | 81.0 | |

| 8 | 27 | 91.2* |

| 26 | 87.8 | |

| 25 | 84.4 | |

| 24 | 81.0 | |

| 23 | 77.6 | |

| 22 | 74.3 | |

| 21 | 70.9 | |

| 9 | 27 | 81.0 |

| 26 | 78.0 | |

| 25 | 75.0 | |

| 24 | 72.0** | |

| 23 | 69.0 | |

| 22 | 66.0 | |

| 21 | 63.0 | |

| 10 | 27 | 72.8 |

| 26 | 70.2 | |

| 25 | 67.5 | |

| 24 | 64.8 | |

| 23 | 62.1 | |

| 22 | 59.4 | |

| 21 | 56.7 |

——–

* Gears appropriate for racing on hard tracks. The ratio 8 x 27 (91.2”) would probably require chain lengthening and subsequent shortening again for other ratios. Ephgrave No.1 owner Mario Romeo notes on CL that ‘taking links out of block chains is not easy’.

** Ratio 9 x 24 (72.0”) suitable for medium gear 25 mile TTs.

The ideal for racing on hard tracks would be chainrings 23, 24, 25, 26 and perhaps also 27 and rear cogs 7, 8 and 9

Posted: Tuesday 18th August 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.