G B brakes

Posted: Tuesday 21st July 2020

Post World War II Britain saw many new companies founded by those who had gained experience in the aircraft and armaments industries during the war. The cycle industry was no exception – pre-war very few British companies had used aluminium widely and those who had done so had often abandoned the material after some experimentation due to problems with reliability. But the new expertise gained during the war was soon put to good use.

GB Cycle Components so named after its founder Gerry Burgess (and not Great Britain as many presumed) was one of the most successful and influential. Gerry Burgess must have been very quick off the mark for the first announcement of the brakes was made in Cycling magazine in November 1945. Pictured were a side-pull brake calliper made from aluminium stampings and a lever in the so-called ‘hooded’ style also made from aluminium stampings.

They were certainly not the first aluminium brakes – pre-war Constrictor had marketed for a short time aluminium brakes almost certainly made in France and several continental manufacturers – Gloria, Lam, Bowden, Weinann and Univerrsal had all made straightforward aluminium side pull brakes. Most were a little flimsy with not enough aluminium used to replace the steel normally used. The rise of road racing in Europe had also changed the purpose of brake levers – they were now used as hand rests as well as levers for operating the brakes. Rubber hoods to cushion the riders’ palms and a change to the shape of the lever housing made riding on the ‘hoods’ an extra alterantive to the bars. Lam from France are generally credited with being the first company to change the shape of the brake levers to make suitable for riding on the hoods.

The top brake made in Britain for clubman and time triallists machines was the Resilion, a horribly complicated affair which was called the Cantilever but bore no resemblance to modern cantilevers and had to be manufactured in at least five different sizes for the front brake alone and which took more than hour to fit each brake. Without a quick release of any sort it was useless for the fast growing sport of road racing.

GB’s brakes were like a breath of fresh air in 1945. Within a couple of years GB had a couple of British competitors in the aluminium side pull brake market, the Burlite and the Strata but neither was ever as successful as GB and died by the wayside in the early 50s. By 1948 the brake which is now known as the Hiduminium (right) (it was officially called the Standard) was introduced. The word Hiduminium was heavily stamped into one of the arms – the only GB logo was a faint small one near the cablle anchorage. Hiduminium was actually the trade name used by Reynolds for many of their aluminium products. The adjustment slot was very long enabling the brake to be used with either 26in or 27in wheels – many frames were built to accomodate both sizes of wheel but the brake reach needed with 26in wheels was 15mm more than with 27s. An extra long reach brake, the Grand Tour which was never made in large numbers was introduced soon after the Hiduminium. GB also started to diversify into making handlebars, stems, wingnuts all of which were to prove very successful.

The most important new introduction came in 1950 with the Coureur (left)intended as the name suggests for road racing with a cam-operated quick release on the calliper. A new brake lever with cast hooded lever housing with a built-in thumb wheel adjuster was introduced at the same time. This was GB’s classic brake modified in 1953 with nylon bushes on the pivot bolt, tarted up with red GB pivot bolt front nuts in 1957 and continued in production until the late 60s. During the 60s versions anodised red and blue all over also appeared.

A simpler version of the Coureur, the Sport without the QR appeared in 1953 intended initially just for the OEM market – this was later sold as an aftermarket product.

Later important introductions were the Coureur 66 centre-pull brake in 1961 at a time when centre-pull brakes had become very popular in the peleton and the Syncron, a dual pivot brake in 1964. GB had developed a close relationship with Altenburger, a German manufacturer and it is quite possible the Syncron was their design.

The last GB brakes were made in the 1970s – they were really quite low-end products. But GB continued with bars and stems into the early 1990s. And GB has survived – it diversified into tubular furniture in the 1970s and is now one of the largest suppliers of conference furniture in Europe.

See http://www.oldcyclebits.co.uk for photographs of most GB brakes and some catalogue illustrations.

GB brakes Timeline:

1945 GB announce brakes in Cycling

1948 GB Hiduminium (Standard), Grand Sport

1950 Coureur brake

1953 Sport brake

1957 Coureur Plus brakes with new version of the Superhood lever with pressed aluminium lever body in place of cast body Sport MkIII brake

1959 Riviera brakes

1961 Coureur 66 Centre-Pull brakes

1964 Syncron brake

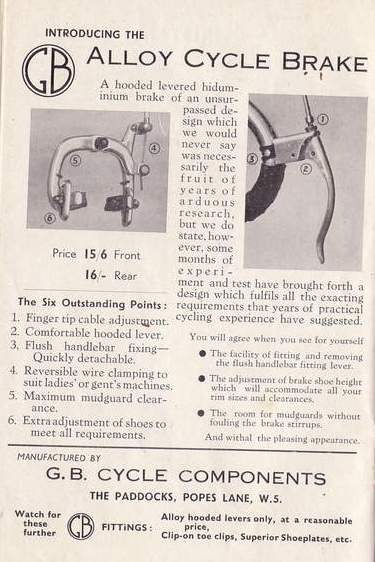

This 1945 advert showing very early GB Hiduminium brakes has recently come to light thanks to Phillip Easton. It is one of the first printed references to this product and was published in the programme for Claud Butler’s 1945 Victory ‘Do’.

It clearly shows the early version of the GB lever which has the ‘hood’ of a slightly darker finish than the lever. The brass fingertip adjuster sits in the top of the lever unlike the later versions where the adjuster is built into the hood.

In this very early version of the Hiduminium stirrup the word ‘Hiduminium’ is not embossed on the stirrup arm, as was the case with the later production versions.

Posted: Tuesday 21st July 2020

Contents

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.