Simplex Retrofriction levers

Posted: Friday 12th June 2020

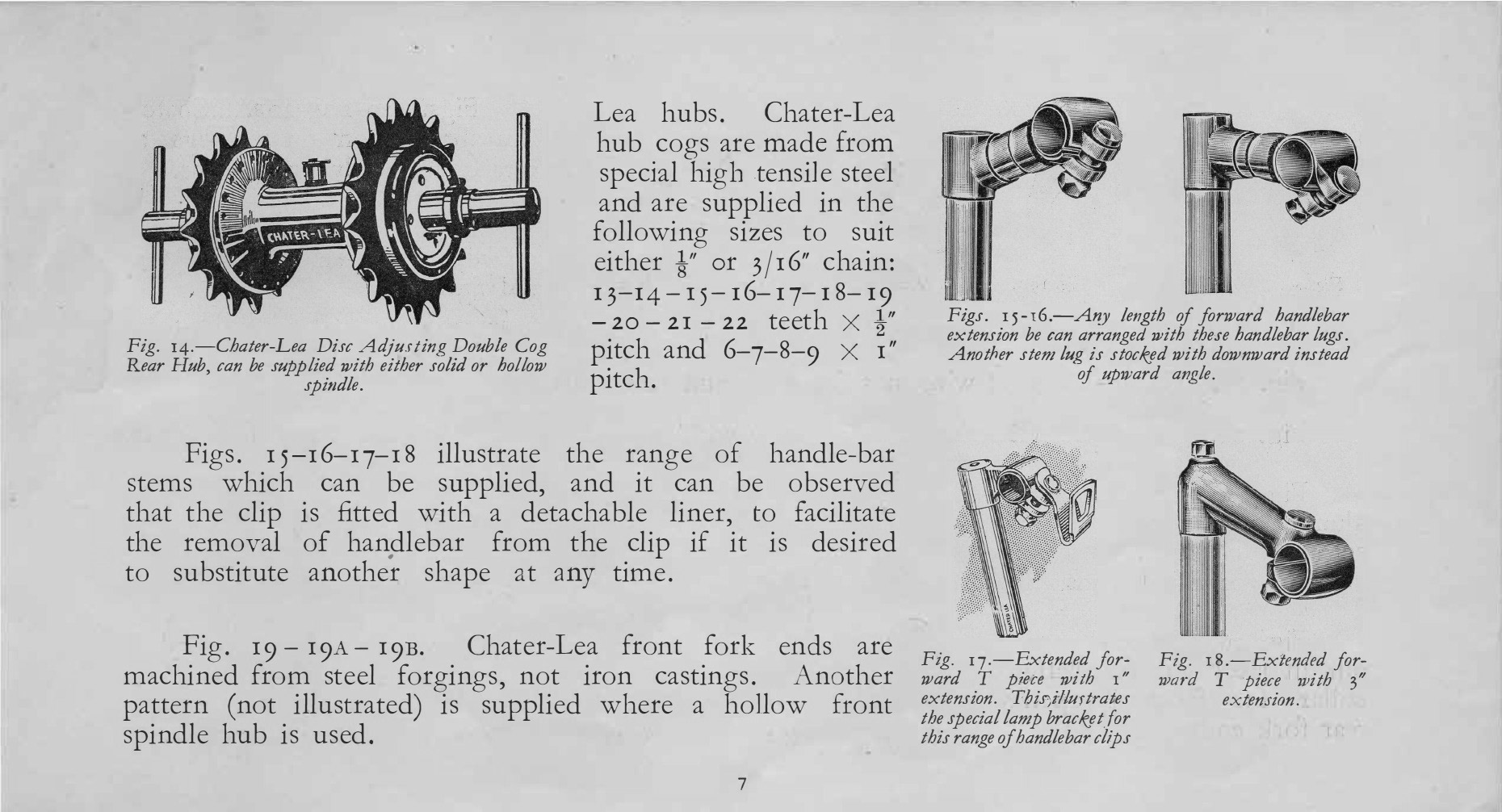

The Simplex Retrofriction down tube levers were introduced in 1973 and they soon became a favourite amongst road racers who, John Spooner tells me, replaced the somewhat temperamental Campagnolo levers with these more refined and easy to use models. The levers have a balancing spring to reduce the likelihood of the lever slipping and as a result can be set up with less tension which makes them smoother in operation.

Under extreme racing conditions the Campag levers had to adjusted very tightly to avoid them slipping from bottom gear at a critical point on a hill climb. This made them quite hard to use accurately for other changes.

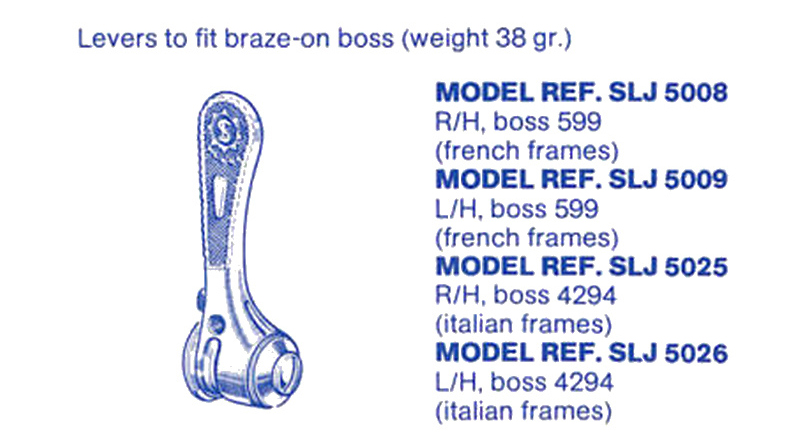

These levers come up for sale from time to time but usually they are in braze-on format, i.e. no band-on included. Simplex bands can be found but strangely the bolts will not screw into the bands as there is a difference in thread, one assumes there are different threads for different levers within the Simplex range. The bolts are very close to 5mm but not quite the same. You may find that the bolts supplied with the levers don’t fit and neither do the 5mm so there must be another, very similar, thread used. I have run a 5mm tap through and used 5mm stainless bolts on the levers shown so hope this will do the trick.

The Dancing Chain states that Simplex also produced a bar-end version of the Retrofriction levers but I don’t have any of these as yet.

Later versions of these levers had AK securing bolts in place of the earlier slotted ones shown here.

I agree with your comments about Campagnolo down tube levers, they were the Achilles heel of the system. I once saw Sid Barrass lose a race on a steep hill when his gear lever slipped. He shouted out for a screwdriver, and the bunch heard him and rode away! I used the centre bolts with the little D rings on them and a shakeproof washer behind them, but they still slipped.

I have a pair of retrofriction levers, braze on, which are quite the nicest I have ever used. Robert Miller used a pair in the Tour de France with Campag gears.

My theory is that the braze on type were imported to fit Campag brazed-on lever bosses which were almost universal in the UK, hence the centrebolts will not fit Simplex lever bands. I actually preferred band on levers as they were more robust and the thread wore very quickly on the Campag brazed-on bosses. Presumably the Simplex band-on had the standard Simplex threading. I know Simplex produced standard handlebar end controls in the 1960s but I have never heard of a retrofriction model.

Incidentally, I have used Campag bar-end controls for 50 years without realising they had an allen key tightener. We always used to tighten them by screwing them in with the leverage of the gear lever. How stupid can you get? The only drawback to applying leverage clockwise to the campag thumb lever to tighten the internal spring was that it was not very tight and could loosen,sometimes when riding! Your system seems a lot more stable. The other thing I never mastered was threading the internal gear wire around the handlebar control without kinking it and also getting the tiny nipple in the hole.

I did read an article once, possibly in Sporting Cyclist where a Belgian pro team mechanic advised against handlebar controls, saying they were unreliable in the rain, but I could not understand this as they were universally used by top pros like Rik van Looy and Tom Simpson.

You sometimes come across these levers without the ‘Simplex’ lettering. I believe that these were made by Simplex for Mavic and sold as part of the Mavic groupset. I have used Simplex retrofriction levers with Campag braze-ons without a problem but I think there may have been two alternative types of screw thread available. French frames usually had some weird French bicycle thread so Simplex would have had one type for that and another for compatability with Campag. Of course you can always swop the original Simplex fastening screws for allen-head bolts if compatability is an issue.

I’ve messed around with Simplex Retrofriction Levers since about 1975. I remembered that there were at least 2 different screw threads used by Simplex to mount their levers back then. For some reason I was thinking they were the industry standard M5x.8 plus M5x.7 or M5x.75 but that may have been Huret levers.

It’s been almost 35 years so the other night I checked out the threads on about a dozen Simplex levers that I have:

ALL of the Retrofriction levers that I have or that I’ve seen use M5x.8 screws. This includes the clamp mounted ones too.

I checked some old Simplex clamp on levers with the plastic wing nuts used to tighten the hex head screws. Both the plastic Prestige levers and the metal Criterium levers that I checked all had M5x1.0 threads.

I have several pairs of what I suspect are Italian made clamp-on Simplex metal levers. the levers themselves are aluminum with plastic caps. The rest of the metal parts are zinc or cadmium plated rather than chrome and they have slotted button head screws instead of wing nuts. They both had M5x.8 screws.

I have several NOS Simplex clamps. One is the old early 70s style with a round raised “S” in the middle of the narrow band. The other has a wide band with an “S” in the “sun” logo. Retrofriction levers fit on both of them but the old one takes M5x.8 screws while the newer one M5x1.0 screws.

So what does this mean?

Simplex Retrofriction levers “should” fit on any Campy style braze on lever boss with a M5x.8 screw thread.

Note, some of these levers have longer M5x.8 screws than others. The boss may need to be (gently) chased out with a tap first or else the screws may need to be shortened.

Many Simplex Retrofriction levers just have a nylon washer holding the screw into the body. If I remember correctly, some of the early ones used metal snap rings to retain the screws. They were hard to remove.

The early levers had the chrome plated, slotted button head screws. The slots stripped pretty easily. Once that you removed the original screws you could replace them with any M5x.8 screws with the correct thread length (including Campy “D” ring screws).

If you are looking to convert some Retrofriction levers to clamp on, make sure that you find a clamp that takes M5x.8 screws.

Everything stated above is subject to the whims of Lucien Juy’s unpredictable reasoning!

I was recently looking for period components for a 1980’s steel racing frame I’ve purchased. I already have a lot of the bits I require — it will be expensive otherwise! — and these bits include some retrofriction gear levers.

I possibly won’t use these gear levers for this project as I have some Campagnolo levers I might use. However these retrofriction levers are NOS I’ve had for well over 20 years and slightly different from the levers pictured on your site. So I though I’d send a few photos in case they might be of use to you in adding a further nugget of information to your site.

The levers are the unbranded braze-on levers made for Mavic. They’re also the later type where the slotted button fixing screws have been replaced by allen key fixing screws.

Attached are three photos:

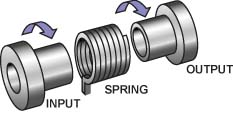

I came across the article on Simplex levers. It is stated that the levers have a balancing spring, but that is IMHO not correct.

Shimano barcons of that age had a balancing spring to counteract the spring in the derailleur so less friction is needed in the lever which

works both ways. Loosen the cable and the handle moves up.

The Simplex Retrofriction uses a closely wound spring around a barrel as a directional clutch. Rotated in one direction the spring opens up for less friction,

rotated the other way friction tightens the spring which keeps the adjustment.

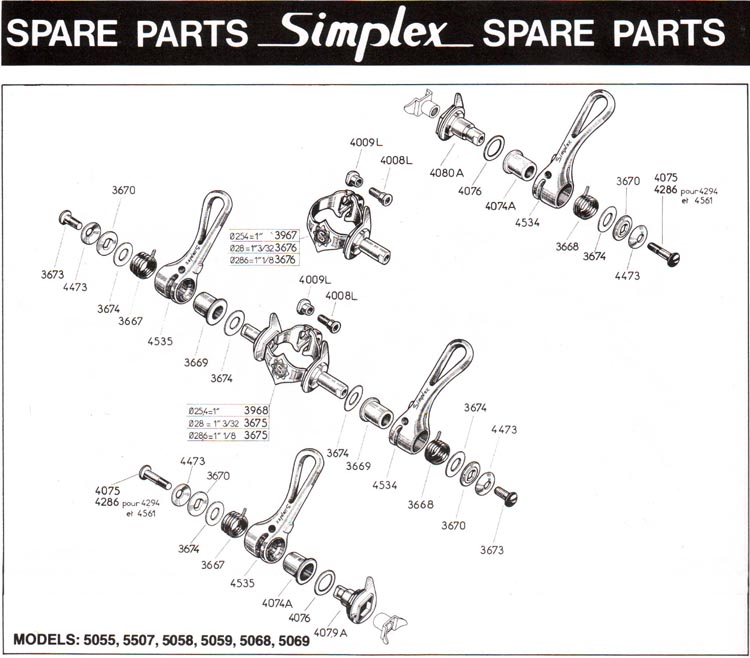

The levers can be taken apart, they will probably respond to cleaning and regreasing .

the springs in these levers are more correctly referred to as ‘drag springs’; they are directionally wound around a drum such that when you pull the lever back, (downshift RD) the spring opens up slightly and slips around the drum. However when the lever is pushed away from you (upshift RD) the spring tightens around the drum, and the drum moves against a standard friction clutch. (Capstans on boats grip ropes in a similar way to how a drag spring works).

Hence the downshift friction is low, and the upshift friction is adjustable (as per a normal friction lever). Cunningly (and in complete contrast to standard friction levers), because the friction clutch is only ever driven in one direction, it tends not ever to loosen, even if the first washer (with two flats on it) becomes a slack fit on the dummy boss.

I have another two variants of the levers:

1) a simplex retrofriction lever with a solid end (i.e. without the loop in it) and the simplex ‘star’ logo in it and

2) the usual open loop type, but with ‘Spidel’ branding rather than simplex.

Posted: Friday 12th June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.