Harden hubs

Posted: Thursday 11th June 2020

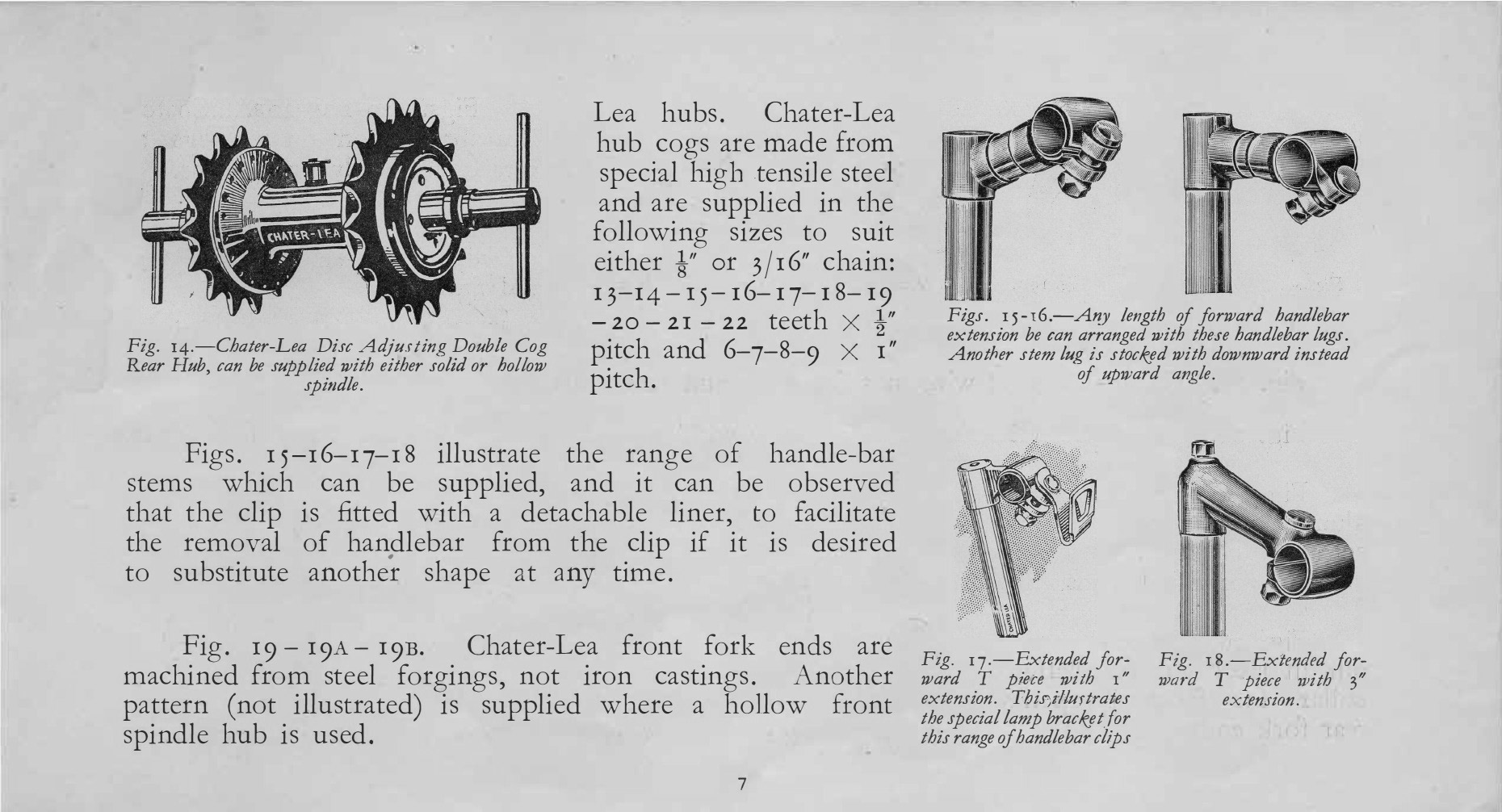

Harden hubs were manufactured in the UK in the post-war years. Unlike many makes they were machined in alloy from a casting. They were produced with small-flange, large-flange solid flange and large-flange drilled flange. They also produced in very small numbers a large-flange version with an integral freewheel – see below.

Most Harden hubs were built with cartridge sealed bearings but they did produce a cheaper version known as the Flyweight which had conventional cones, ball bearings, etc. In spite of this the more expensive model seemed to outsell the cheaper by many times.

Alex Von Tutschek has opened his treasure chest to let us see his 1950 Harden Unit Free-Wheel Hub. A bulge on the inside of the drive side of the hub contains the free-wheel ratchet on an internal barrel. This slides over the axle which is already supported by two ball races. The barrel has two more races so the whole thing is very well located, obviously not noted at the Campagnolo works. It was available for 3 or 4-speeds with the option of a ‘special’ 5-speed. Alex points out that there is a large void in the hub so although there is a grease nipple fitted one would need a grease-gun full to fill it. I assume the grease is kept away from the pawls! Note Harden wing nuts.

Harden Freewheel hub. Part No 1200 – text and image by AVT

This device was available for a short period in 1949/50, it combined an Harden alloy hub with a in-built freewheel and looked quite attractive.They were built for 3 or 4 speed on 1/8″ chain or 5-speeds with a 3/32″ .and have four ball races within. The weight of the unit less the sprockets was 14 1/2 oz.

These are very rare today and few are know to have survived.This writer has just traced the gentleman at Harden’s who was responsible for the design of this product.There will be more information to add very soon.

Shots of my favourites, Harden Flyweights, these had conventional cup & cone bearings and were only available in gear-fixed large flange.There are two different versions, one with single curves on the inner surfaces like a normal Harden hub and the second type, as in these photos with a triple curve very much like an alloy Campag record hub.The latter are the prettier and , I surmise, the later ones and probably among the last Harden hubs available. One anorakish observation having seen quite a few of these is that some have stamped trade-marks and some don’t. The man at “The Harden Tool & Die Co” who was responsible for stamping the trade-mark on their hubs should have been boiled in brake-fluid for gross incompetence.

Another of the rarer Harden hubs known as the Bacon Slicer for obvious reasons.

The front one shown here is in a pair of Bates Diadrant forks and built up with 15/17 double-butted spokes.

Not to outdone here is one on the rear of the Bates with the rear-end adjuster working on road ends rather than the usual track ends. A lot of the Bacon Slicers were single-fixed rather than double-fixed. When sales of this hub slumped towards the 50s some of the stock hubs were drilled in the factory to convert them into the conventional drilled hubs. Often these drillings bisected the Harden logos.

There are gear-sided Bacon Slicers but they are very rare.

The rear-end adjustors are of course designed to stop the wheel pulling over under pressure and also they ensure that the wheel returns to the correct position when replaced in the frame after a puncture, etc.

For more on servicing Harden hubs link here.

Posted: Thursday 11th June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.