Wrigley, Hilton

Posted: Saturday 06th June 2020

Hilton Wrigley was probably the most unlikely frame-builder that I have ever met. In 1952, he was also the first one, and his work immediately set the standard by which I was to judge all the others I have met up with since.

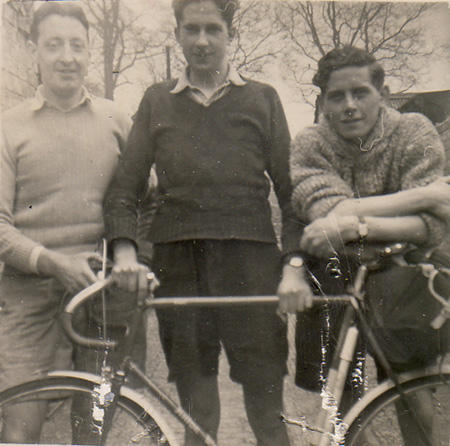

Living in the small town of Marsden, the last outpost of the former West Riding of Yorkshire, at the foot of the long climb of Standedge pass, Hilton was not at all well-known as a cyclist nor did he even have a bike-shop. In fact, Brian Haskell, former star rider of the Huddersfield Road Club and later Independent for Viking Cycles, who was among the first to buy a “Wrigley”, told me recently that he had never actually seen Hilton on a bike.

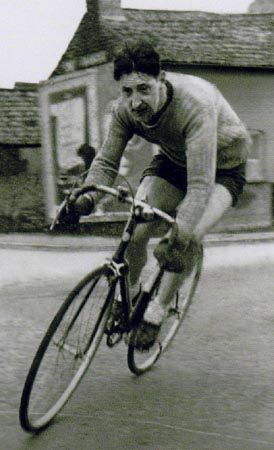

My first sighting of a Wrigley – and it was love at first sight – was as I was descending Chapel Hill, Huddersfield in my best imitation of Fausto Coppi, just as flyweight climber, Brian Haskell, was honking effortlessly up in the opposite direction.

Now my bike was a Cyclo Benelux-equipped Rotrax ‘La Premiere’, with curiously shaped cast lugs, resplendent in its salmon pink enamel with black head and seat tubes. I had travelled all the way to London on a Yorkshire Traction bus to visit Jack Bagulay’s cycle emporium at No. 48 The Crossway, Stoke Newington, just around the corner from Harry Rensch’s Paris Cycles to buy it. In his minute one-roomed shop Jack used to buy second-hand bikes, dismantle them and sell off the parts.

All this was back in 1952 and Haskell’s bike was a revelation. The track frame was finished in plain white enamel with a Post Office red flash sprayed on the down tube, on to which were placed ‘Olde English’ transfers that spelled out the name Hilton Wrigley ..all very minimalist. It also sported the very first TA 5-pin alloy cotterless chainset that I had ever seen..much better than my Gnutti steel one.

Word about “Hiltons” rapidly spread around the Huddersfield peloton and soon more and more riders from the very influential Huddersfield RC started to leave their Gillotts, JRJs, Ellis-Briggs, and Carltons in the shed, and to sport their new Wrigleys. Friday tea-times outside Wiley Bros cycle shop in Trinity Street soon saw Wrigleys out-numbering all other brands. Similarly in Wednesday evening 10’s on the Denby Dale hilly course, Wrigleys started taking all the honours.

It was not difficult to find Hilton’s workshop, as his head tube transfer said it all – Hilton Wrigley, Marsden – just a pleasant undulating ride up the Colne valley.

Hilton’s first workshop was a very uninspiring small square flat-roofed block of a building situated on the edge of the shunting yard next to Marsden’s LMSR railway station. It was probably a plate-layer’s disused shed. As word spread around members of the Colne Vally Cycling Club, often known as the Wheelers, adopted Hilton’s workshop as their clubhouse..and most of them, such as myself, bought his frames.

Hilton was by training an engineering draughtman, employed full-time by Brooks Motors, makers of electric motors; frame-building was his hobby, a hobby that found him most evenings and week-ends in his workshop creating very attractive frames with elaborate lugwork.

Hilton soon moved his workshop into an empty shop/house on Back Lane in the centre of the small town. Here he had more room to build his frames, a small window to exhibit a few accessories, but more importantly more room for his customers to mill around in, and for the Wheelers to take over as their clubroom. Friday evenings witnessed frame-building on the left of the front door and darts on the right.

Hilton did all the preparation of the tubes and the brazing up, using an oxy-acetylene torch, but was assisted by a chap called Fred who was the lug-cutter. He too was part-time. Usually cast lug blanks were used, these being either painted white with the outline of the lug being drawn on, freehand, with a blue ball-pen, or Engineers’ Blue was used and the outlines scribed through the finish. No templates were used. The designs were cut by drilling, sawing with an Abrafile, and then filing and tidying up and thinning down with needle files. As Oscar Egg Super Champion pressed lug blanks became available, they too were used.

It was quite common, on Friday nights, at Hilton’s, for cyclists such as Haskell and clubmate Dennis Scholes, both skilled metal-workers, to help Fred with the preparation and cutting of the lugs. Brian also used to help with some of the repairs and odd jobs needing brazing.

All Wrigley frames were custom-built, with four models generally being available, each one designated by the name of the lug design. The basic model, the Competition, usually used ready-cut Oscar Egg lugs, with Nervex Pros only appearing much later on. Like so many Yorkshire builders such as JRJ, and Whitaker and Mapplebeck, Egg lugs were favourites. The next model, cut from EKLA cast blanks had large simple twirls resembling bigger Egg SC3 lugs- the model on the L.H Brooke’s frame on this site’s Oscar Egg page. Then came the Superbe model, all scrolls and long spearpoints, and finally the International..a very individual design, unlike any other frame-builders’. This is the model in the accompanying photos.

Hilton did not use any jigs when building frames, just a few gauges and a reliance on the “old crossed string” method of tracking up the rear triangles. His workmanship was meticulous as was his taper filing and thinning of the lugs both before and after brazing. The intricacy of the lugwork – International models being very popular – often gave rise to problems of cleaning up the frames after brazing. Because he had no sand-blasting equipment , all the lugged joints were fluxed up with borax paste which was then left to dry in situ. When the flux had hardened, Hilton used to very carefully remove as much surplus as possible with a combination of of tooth brushes and artists’ fine brushes to ensure that as little brazing spelter as possible would be left in the profiles of the lugs. It was a very tedious and time-consuming activity. The arrival of a sand-blasting company nearby revolutionised his productivity.

Spraying was sub-contracted out to Ellis-Briggs’ in Shipley, with good solid enamel finishes being preferred as these set off the contrasting flashes on the down-tube. Polychromatics were an option as were flamboyants. The Olde English transfers were the original design, with the copper-plate type being introduced at a later date.

Although Hilton’s frames were very popular and ridden by the majority of cyclists in the Huddersfield area, no one appears to know when he started buildlng frames, or why..although the date of the late 40’s or, more likely, the very early 50’s is accepted…or when he gave up, although the early 60’s is assumed. He was not a prolific builder, just a local one serving local cyclists, nor has anyone any idea how many frames were built. One of my own Wrigleys, a Superbe model, is numbered 4094. That could be No. 40, sequentially made in 1949. but more research is needed.

Until more research is done and more frame numbers collected, assumptions will have to be made. Probably Hilton, who was thirty-nine when he started building, did so to supply frames to the long-established Colne Valley Cycling Club, of which, it is rumoured he had been a member. He died in 1977 at the age of 67 from a heart attack. In 1976 when I met up with him for the last time, he was very bitter and stated that frame-building “..was the daftest thing he had ever done!”

Bill Burns was a work-mate of Hilton at Brook Motors where he was a fitter and a workshop chargehand.

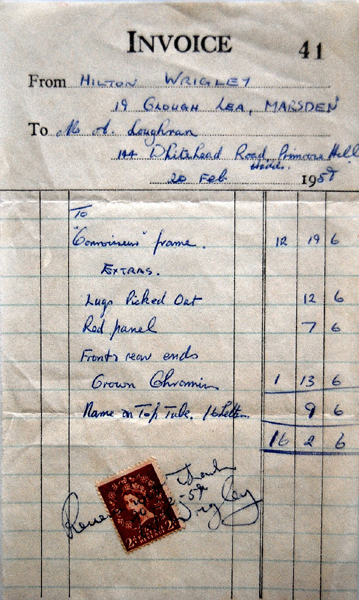

After discovering the Hilton Wrigley page on Classic Lightweights, we were contacted by Andrew Loughran who purchased a Connoisseur path/road frame from Hilton in 1958. He provided the original invoice – images of which can be seen above.

Posted: Saturday 06th June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.