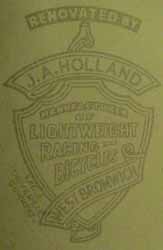

Holland, J A 'Jack'

Posted: Tuesday 02nd June 2020

My father was always known as ‘Jack’ to all his customers.

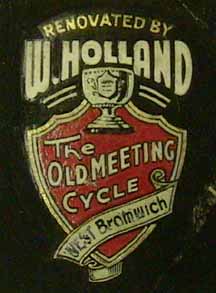

The firm was started by my grandfather, W. Holland. At first, it was situated at 122 Old Meeting St. (*see note at bottom of page), then some time before WWII, they moved to 106. My father had an elder brother, also William, who was killed in the war, and a younger sister, now also deceased.

After being demobbed, my father returned to the business and carried it out until the property, and those surrounding it, were compulsorily purchased for demolition to make way for road improvements. This was in the mid 60s. Previous to this, my father was having difficulties carrying on because the firm supplying the tubes (I think it was TI) began a policy of only supplying very large amounts for any order, which was impossible to accept. This would mean the end for small businesses and craftsmen like my father.

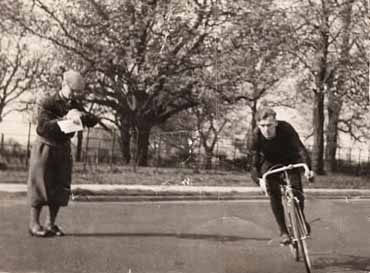

In the shop he had a special board against which a customer would stand to have exact measurements taken for the best proportion of the frame to give the most efficient ratio for speed. Nearly all the racing bikes were made to order as ‘one-offs’.

I remember some details about my father’s workshops and the kind of processes he carried out there. He began with the bare tubing, and made the frames completely. He did the brazing and welding himself. He had an area with two large tanks into which the complete frames were lowered. My mother says that one of them was used to clean completely a frame before it was enamelled, removing things like greasy finger marks etc, which would have prevented the enamel from adhering properly. She also reminded me of the two ovens which my father constructed, to be used for the stove enamelling processes.

The hangers to suspend the frames were made from old spokes which he bent into hooks (‘waste not, want not’ could nave been his main byword). The enamel finishing was done in another part of the workshop. He had a spray gun for this. Lug lining and transfer fixing were done by hand.

A big treat for me in the school holidays was to go with him in the van to the ‘shot blasters’ or the ‘chromium platers’. These small firms were situated in Birmingham, but I don’t know exactly where. Old Birmingham was full of small places with their own specialities like this.

The noise of a hacksaw cutting through a tube, with the sound of the note it produces gradually falling in pitch instantly, returns me to childhood when I watched and heard this process happening so often.

The photograph of a Jack Holland in Readers’ Bikes on your website is beautiful, but I think that originally most of these special machines would have more delicate and detailed enamelling. Usually there was a base coat of one colour, and then my father made a contrast with another colour by skilled work with the spray gun. He would make one colour gradually fade into another, an effect which I have not seen elsewhere (the owner of this bike describes it as originally having such a finish). He was very skilled at this. He had a colour chart sprayed on to an old fork, and would also do special requests from the customer, who did not want his machine to look the same as anyone else’s. Plenty of time was taken over this aspect of an order.

My father did all the finishing by hand, lining the lugs with a very fine paint brush. This was a job he did in the evenings when the shop and workshops were closed. In the winter he would do this in the living room, giving the excuse that the paint must be kept warm in order to have a place by the fire. Another job done in the evenings was ‘trueing wheels’.

A popular choice for roadsters was ‘gunmetal’, although these were not usually given the same fancy treatment as the lightweights.’Knockin Bags’ were made as a sideline in our shop, by my mother and me. She had a sewing machine and made up bags in strong canvas. The bags had a long canvas strap and it was carefully measured so that the bag did not go low enough to interfere with the rider’s control of the cycle. The contents were employed when the cyclist had a knocking sensation from his stomach. I was allowed to help in the cutting out and easy sewing parts. These were also known as Musettes which is, of course, French for bagpipes. I guess the bag was called this after the shape.

Mrs Edith Holland remembers that the frame numbering was under the bottom bracket and consisted of the month, followed by the year and then the frame number, e.g. 3 56 1234 would be frame no. 1234 completed in March 1956. Robin Walker has Holland frame no. 25717. So it dates Feb 1957, the 17th one built that year. I will try to remember the names of some of the customers, who always came into the house for a cup of tea and a chat.

Posted: Tuesday 02nd June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.