Resilion

Posted: Friday 12th June 2020

Resilion is a name synonymous with one product, cantilever brakes. Throughout the 1930’s they were one of the hallmarks of a quality lightweight. As this article will show they produced not just one of the more innovative and efficient brake designs but also other brake and cycle component design. Although all subsequent brake design developed along completely different principles it is interesting to note that when in the 1990’s Shimano introduced their direct pull (V) brakes they copied the Resilion idea of long brake blocks curved to follow the rim. In fact Shimano V brakes pads will fit Resilion brake shoes. These brakes have now replaced cantilevers as the standard brake on all bar racing bikes and the cheapest mountain bikes.

The Origins of Resilion

The Resilion Company was founded in 1927 for the manufacture of a saddle top made from sponge rubber. It was this product that gave the company their name. Originally employing two people the design was an immediate success. Mentioned in glowing terms in the CTC Gazette’s review of the 1928 Olympic show (1), it was recommended as a cure for saddle sores and general saddle discomfort (2). By the early 1930’s they produced a variety of models designed to fit all standard saddles. In this year they changed to cowhide for the outer cover, a change publicised by featuring a 60 square feet cowhide on their stand at the Olympic show. In 1933 prices ranged from 14/6 to 18/6. In additional to the saddle tops they also sold a range of complete saddles all with the tops sewn in.

The Cantilever

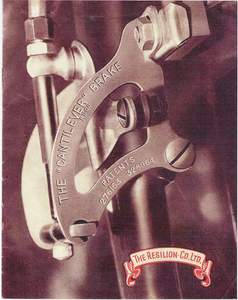

The Resilion Cantilever was introduced in 1929 and launched at the show of that year. Instantly acclaimed as a huge advance in braking , I would go so far to say it was a revolution in braking, until then many cyclists relied upon a fixed wheel or crude and ineffective plunger type brakes to stop. It was awarded the CTC plaque that year for the greatest advance in cycle design (3). Often it is described as ‘ a sound or real engineering job’ .It is interesting to note that there was no award the previous year as the CTC felt there had been nothing meritorious. Writing in ‘Cycling’ on 25th April 1930 in an article entitled ‘The Plaque Test of Progress’ that elder statesman of the pastime (and father of time trialling) FT Bidlake stated the success of Resilion was due to:

“the development which gives each brake block its own separate fixing and own mechanism of application gets away from the calliper as well as the horseshoe….

Added length of brake block increases the contact area.. and the brake design is the subject of the CTC award”

Bolting the stirrup to the frame was the common way of attaching a calliper brake at this time. Using a centre bolt had started in France in the mid 1920’s but was still the exception. The Resilion was extremely popular with both touring and racing club cyclists. Unlike the later generation of cantilevers ( Mafac and successors) it did not require any braze on fitting to the forks or seat stays. Although this may seem like an advantage , i.e. it could be fitted to any frame , in practice the number of different fittings required contributed to the high cost of manufacturing and complexity of fitting.

It is a measure of its effectiveness that it became the de-facto standard for tandems and tricycles. On the latter when fitted to the front wheel it meant the second brake could also be fitted without the need for any braze ons. Higgins fitted Resilion as standard equipment on many of their trikes well after WWII. Until post WWII advances in brake design it reigned supreme as the quality brake for lightweights.

The brake was invented by Mr L T Marr who became the managing director of the company. A keen cyclist and member of the Bath Road Club he died in 1936 (4). Marr was only 52, a contributory factor may have been the fact he was gassed during WW1 but both his father and brother died at this age. Marr’s father had run a plating business in Clerkenwell and also did some light engineering.

Marr would travel around Europe by bike dressed in a Norfolk jacket and deerstalker demonstrating Resilion brakes. He lived in Hornsey, North London which was quite a select area then, his main none cycling interest was collecting Persian carpets. Marr left quite a substantial fortune to his nephew Harold who unfortunately had a weakness for slow horses and fast women and thus it was quickly squandered.

He was not just a gifted inventor but also extremely good at marketing. You realise his achievement in getting the lightweight trade to adopt these brakes when you consider just how complex they were and the amount of fittings a dealer would need to hold for different sizes of fork/stays. Resilion became in a very short space of time a byword for good braking. Many of the smaller lightweight builders fitted the brakes as standard : these included Macleans, Selbach and Claud Butler. This even continued after WWII, and early Thanets were also fitted with Resilions. Early Thanets were fitted with a braze on modification for the Cantilette. Brakes were available chromed or black enamelled (slightly cheaper). The early 1930’s models can be identified by having a different shape cut out in the sides of the arm

The original patent application:

GB329211 329,211. Marr, L. T., and Resilion Co., Ltd. June 26, 1929. Brake mechanism; control mechanism. – In Bowden wire control mechanism for the brakes, ignition, &c. of motor and other cycles &c., improved means are provided for relieving the compression on the outer casing and the tension on the wire, and for again applying the compression and tension, without the necessity of altering the usual tubular screw or other adjustment of the control mechanism, in order, for example, to allow easy movement and replacement of the brake blocks to facilitate removal and replacement of the cycle wheel. ,

At a number of the 1930’s Shows Resilion demonstrated the effectiveness of their brake by attaching a 6 lb weight to a lever and challenged the public to try and move the bike forward (5). According to the CTC Show reports the bike was immovable!

From a poetic advertisement:

“Fit a cantilever/Live life’s allotted span/Stop just where you want to/And not just when you can …

…Resilion brakes are better than insurance policies they ensure you remain alive” Cycling 14th September 1934 p17

The brakes were expensive and Marr realised they were out reach of many cyclists in the impoverished 1930’s. His response marketed a cheaper simplified version, the Cantilette. Also known as the ‘B’ this was about 30% cheaper. Introduced in 1931 (but only supplied to cycle manufacturers for the first two years) the sheet metal stampings were replaced by lightweight malleable castings and the brake blocks were shorter.

By the mid 30’s they employed over 200 staff. The success of Resilion is very much linked to the presence of Marr. He was clearly the driving force behind the company. After he died in 1936 there was no further real innovation. There are some parallels with Constrictor and the direction the company took after the death of Leon Meredith. The next change in design was not until 1948 when they introduced a part alloy version (6).

The cantilever was somewhat complex but very well designed. The lever fulcrum was such as to maximise mechanical advantage. In fact so powerful was the lever that cables if they broke at all would be at this end. The cable was in fact three cables soldered into a small flat brass block which slide within its casing when the lever was pulled. At the stirrup end the cables were attached to brake side plate for extra rigidity. The long brake blocks (twice as long as a normal block) dramatically improved the braking. It had a reputation of being difficult to set up and maintain. This was something Resilion sought to counter by stating it could be fitted within five minutes. When fitting the following needed to be considered:

1. Size of frame: larger frames needed a longer cable for the rear.

2. Fitting to forks and seat stays specific to their design eg round, D section, oval etc .This means the brakes were not interchangeable. It is essential that anything fitted to the forks would not come loose as this could cause a serious accident so the fitting needed to be correct.

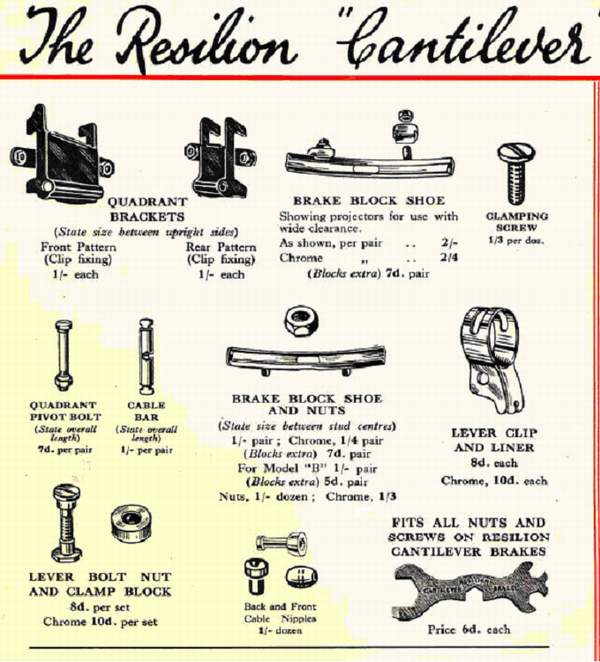

3. Width between stays/forks opposite rim. Resilion offered proprietary brake blocks in three thicknesses to achieve the correct rim clearance. Fibrax provided the following, 3 inches long for Cantilevers and 2 ¼ inches for Cantilettes:

| No. 251 No. 253 No. 260 |

¼” deep 7/16″ deep 5/16″ deep |

Another factor was in use with 1¼ inch and wider tyres wheel removal could be a problem as there was no quick release. One innovative option was to modify the brake block and shoe to enable swift removal of the brake shoe. This was done by J.J. Cooper a small East London builder of frames under The Upton marque. A headless screw was fitted to the open end of the brake shoe and then a knurled nut which could be unscrewed and the brake block would slide out.

Resilion produced a multi purpose tool about 6 cm long for fitting the brakes. They also provided dealers with a wooden box approx 12cm by 10cm by 4cm which had two levels of compartments to hold the specialist fittings required. Supplied with the brakes were steel cable clips for attaching the rear brake cable to the frame.

The action of the brake was extremely smooth quite different in feel to the later Mafac cantilever. The levers work well with other brakes and are one way of improving the effectiveness of pre war brakes .It did not need the fork crown or seat stay bridge to be drilled. Often frames built for Resilion brakes have the rear undrilled as a mudguard fitting could be clipped on over the seat stay bridge.

In the 1949 Holdsworth ‘Aids’ it is claimed Resilion “will stop a bus”. Amongst the range are special versions for tandems ( an extra 2/6). An indication of the complexity is provided by the following note:

When ordering Resilion brakes specify whether the front is required for D ,oval or round fork blades and if rear is for ½” or 5/8” diameter seat stays.

The main problem with the Resilion was that there was no way of adjusting to compensate for an out of true rim.As the brake blocks wore it was quite complex to adjust. As a consequence of the specific fitting for forks/stays the brakes were not interchangeable. This meant dealers had to carry stocks for the different types of fork and stay fittings. It also means when retro fitting them to a frame they will only be fully effective if the correct fittings are used, something I have found out to my cost.

Handlebar grips

During the 1930’s they also made a handlebar grip manufactured like the saddle top from a combination of leather and rubber.

Dynamic Coupling

In 1932 Resilion introduced a means of activating two brakes with one lever. The two brakes were linked by a Bowden cable. This became very popular with tandem riders as it enabled three or even four brakes to be fitted (often combined hub and rim brakes). It became the subject of correspondence in the CTC Gazette and the overwhelming view expressed that it was a great step forward but with the proviso that it was not for the novice; the system was too powerful! According to the December 1932 CTC Gazette the coupling worked as follows:

“in its commonest and perhaps best form it consists of two hub brakes. The hand lever is only applied to the front brake and the arm of that brake instead of being anchored to the front fork is connected by cable to the rear brake. Thus the operation of the front brake converts the front wheel into a lever that operates the rear brake, the bicycles speed being the power, and if that speed is high the power is great and the retarding force is accordingly very powerful and effective. Its is certainly the fiercest “stopper “we have tried “.

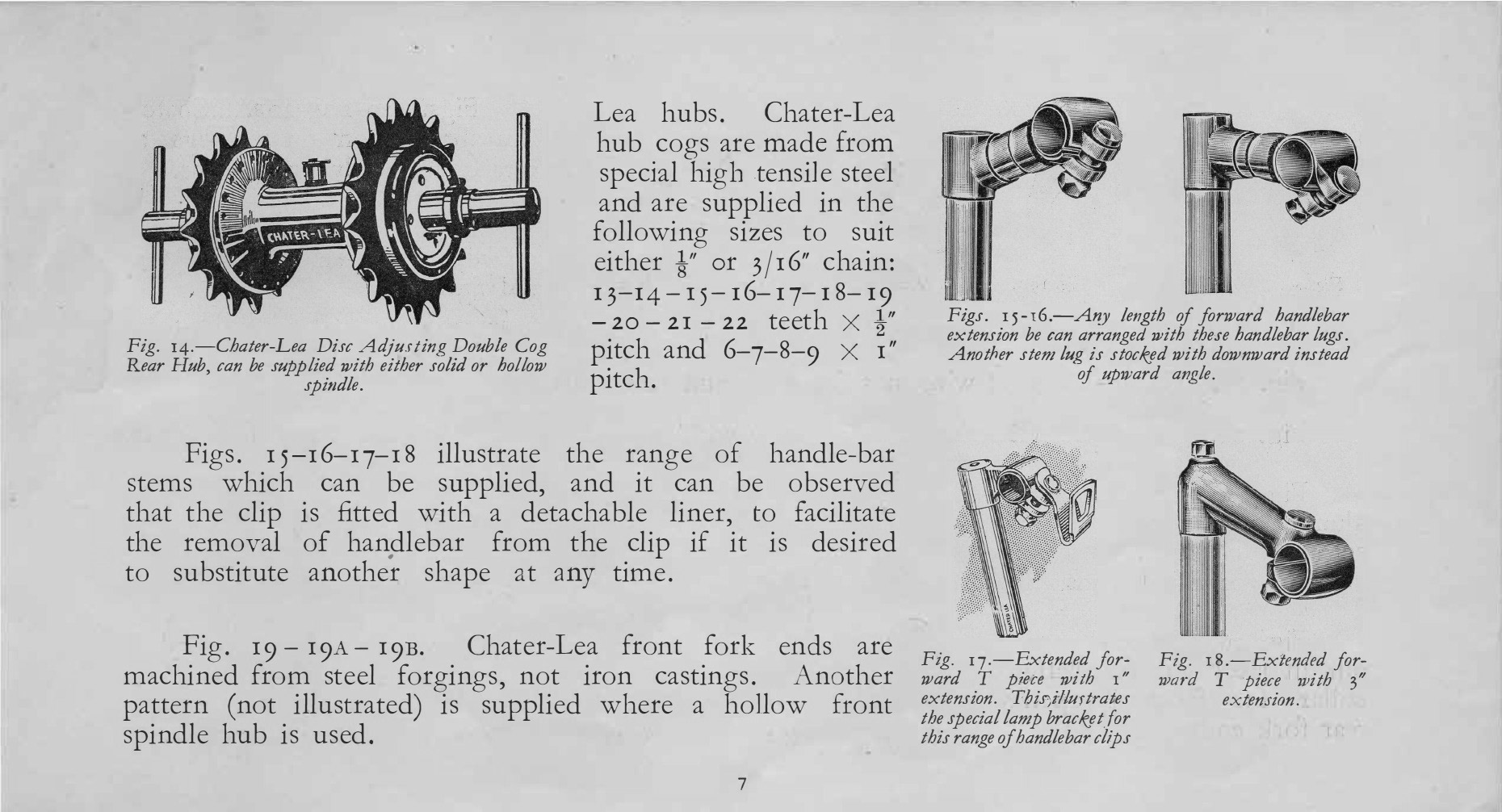

The Anchor

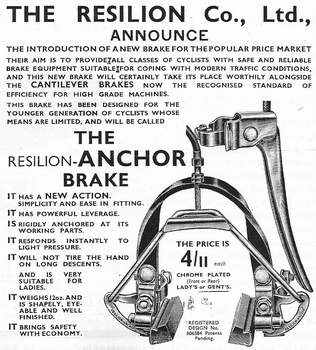

The Cantilever was priced for the top of the market the Cantilette for the middle market. Resilion in 1935 offered a cheaper (or in their language “popular priced for the rider of limited means”) brake, the Anchor (see advert right).

Brake blocks were conventional and the brake arm was clamped to the stays/forks but in operation it was more like a centre pull than a cantilever .

According to a review in the December 1935 CTC Gazette ( p453) it was :

“…a complete departure from calliper action and has great advantage over this type in that it is anchored at its working parts and cannot yield to the thrust of the wheel”

At 4s 11d each it was less than half the price of the Cantilever but was far less efficient brake.

Post War Developments

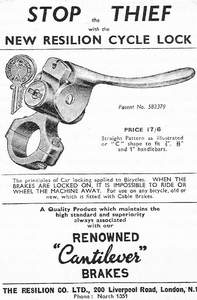

In addition to the alloy brakes (7/5 more expensive) Resilion offered an alloy lever and also red brake blocks designed for alloy rims. According to ‘Cycling ‘ (7) the alloy lever had:

“…the moving parts in the brake lever reinforced by the insertion of steel bushes in the pivot holes, thereby providing a happy compromise with the wearing propensities of steel and the weight saving of alloy…Two types of lever are available; straight lever pattern and the curved C type.”

Another innovation in 1948 was a lever with a lock which when used jammed the brake on

All the alloy products were introduced in 1948. Introducing them Resilion reassured riders that any part that took strain was still made from steel. This reflected the widespread suspicion of the time that alloy was not really strong enough for such a critical component as a brake.

Resilion were clearly losing market share as more and more cyclist opted for the simpler post-war brakes e.g. GB, Burlite, Stratalite. In the December 1951 CTC Gazette they advertised a reduction price of the alloy cantilevers from 32/6 to 22/6. The reasons given for this was a shortage of steel but I suspect by then the brakes were viewed as too complex and old fashioned by most riders and were not selling.

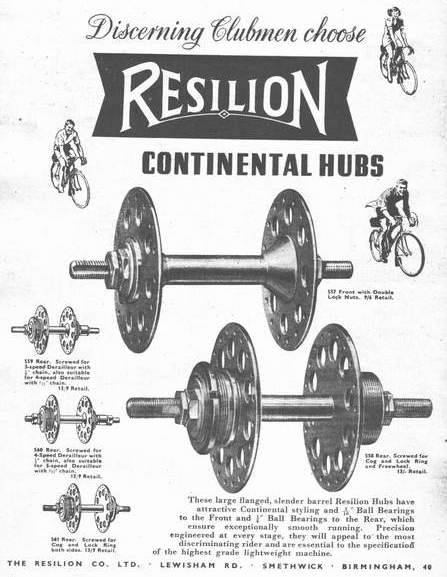

Resilion produced a large flange solid three piece all steel hubs.

It is unclear whether they were made in house of bought in. Throughout the mid 50’s to early 60’s they were fitted as original equipment too many medium to low price sports bikes.

The advert on the right shows the distinctive ‘cone’ between the barrel and flanges

There were two Resilion gears, a 3 speed 1/8 model introduced in 1954. This was a chainstay mounted model which used the same braze on as a Standard Cyclo. It was made by Phillips for Resilion and fitted as original equipment on a number of Phillips cycles.

The last Resilion product was the 1958 Crimson Star with the very distinctive red pulley. This was very similar to the Mk7 Benelux made by Cyclo. It was cheap and robust and had the benefit of being suitable for 3, 4 and 5 speed with 3/32 and 1/8 chains . The only drawback with the design was that the pulleys were unshielded with the metal bushing exposed in the centre. This lack of shielding will cause rapid wear. By contrast Simplex pulleys are shielded.

Some time in the mid 1950’s they moved from Islington, North London to Birmingham. After 1952 they ceased to exhibit at the annual cycle shows. It’s not clear exactly when they ceased trading but the Resilion name disappears around 1961. In the mid 50’s they would seem to have been taken over by Phillips (1955 General Fitting Company catalogue refers to the Cantilevers as ‘Phillips Resilion’). The last version of Resilion brakes came with levers stamped Phillips.

Without a doubt their heyday was the 1930’s. Following its introduction in 1929 within a very short space of time the Cantilever defined the standard for lightweight cycle braking. Failure to innovate after the death of Marr meant they were left behind and after WWII had an ever increasing decline in market share. Post war the brakes were seen as just too complicated and inflexible. For example a key requirement for many racing cyclist is a quick release to enable swift wheel change in the event of a puncture. With the GB this was the flick of a lever on the stirrup or Mafac unhooking the straddle cable, with the Resilion it was just not possible without partial disassembly. The gears and hubs were very much copies of other products so ultimately it is one product Resilion should be remembered for – the Cantilever .

REFERENCES

1. CTC Gazette November 1928 p414

2. CTC Gazette July 1928 p288

3. CTC Gazette October 1930 p 443

4. Cycling 25th July 1936 p96

5. CTC Gazette November 1937 p367

6. Cycling 17th November 1948 p421

7. Cycling 14th July 1948 p28

OTHER SOURCES:

CTC Gazette May 1938 has a six page advertisement featuring pictures of the three brakes and lists major dealers in Britain

Frank Berto : The Dancing Chain 2nd Edition 2005 pp167- 69 and 179. Details for Resilion Gears.

1950’s Brown Brothers catalogues for the Resilion hubs and gears

1949 Holdsworth Aids to Happy Cycling p3

The cycles in the National Cycle Museum at Llandrindod Wells fitted with Resilion cantilevers and cantilettes

The General Fittings Company Catalogue c1955

ACKNOWLEDGEMENTS

Alexander von Tutschek for source material

Peter Brueggeman and Peter Underwood for gear and hub images

David Higman at the National Cycle Museum Llandrindod Wells for allowing me to mess around with their Resilion equipped cycles in the collections

Ray Miller for a copy of the 1934 Resilion catalogue in the VCC library and images of the Resilion spares box

Posted: Friday 12th June 2020

Contents

- Overview

- The Origins of Resilion

- The Cantilever

- Bolting

- The brake

- Resilion

- Advert

- From a poetic advertisement

- The cantilever

- Frame

- Numbers

- Resilion production

- Problem

- Handlebar grips and Dynamic Coupling

- The Anchor

- Post War Developments

- Alloy products

- Hubs and Gears: the final products

- Resilion Gears

- Images

- Resilion brakes

- Rererences

- Other sources

- Acknowledgements

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.