Weinmann components

Posted: Friday 12th June 2020

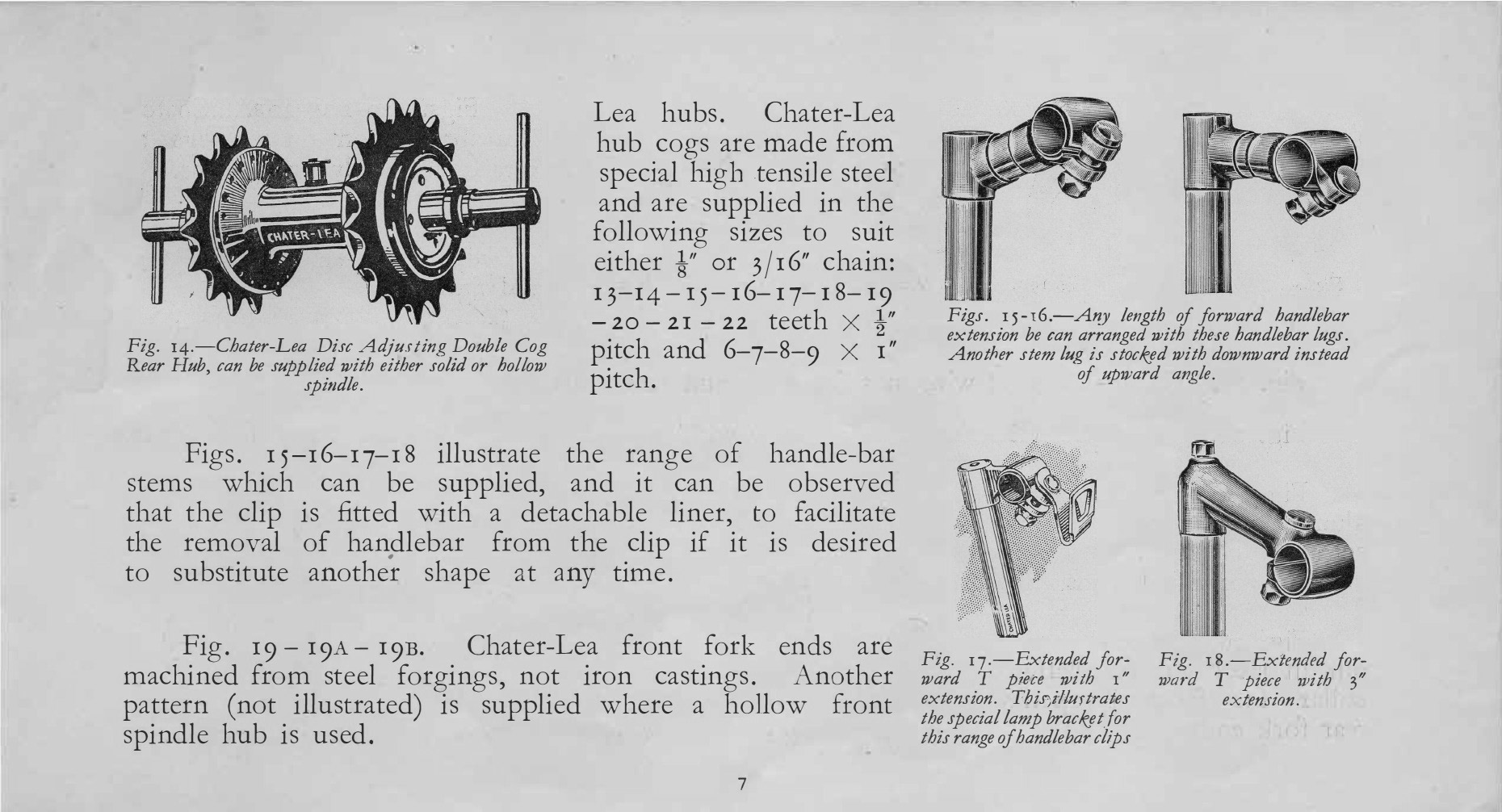

The most well known Swiss maker of cycle parts, Weinmann were a large volume supplier of brakes and rims, especially in the 1970’s when most British ‘sports bikes’ featured Weinmann as original equipment. This was true for Raleigh, Carlton, Dawes and Falcon. Weinmann were most successful with their brakes where they achieved a near dominance of the UK market, only top-end cycles would feature Mafac, Universal or Campagnolo.

GB experienced a gradual decline throughout the 60’s and 70’s with no real innovation after the late 50’s. Other makes like CLB were rarely found on cycles outside of their country of origin (France).

Weinmann were based in the town of Schaffhausen in northern Switzerland and have their origins in the late 1930’s. They started appearing in the British market around 1949 (1). They originally made steel brakes but in the late 40’s began to use forged alloy. Prior to 1946 the brakes did not have a model number.

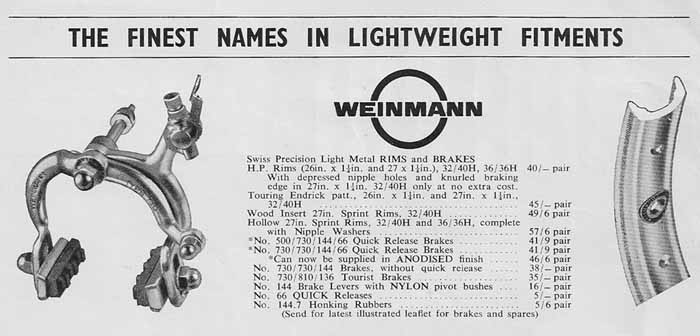

In the mid 1950’s the product range was as follows:

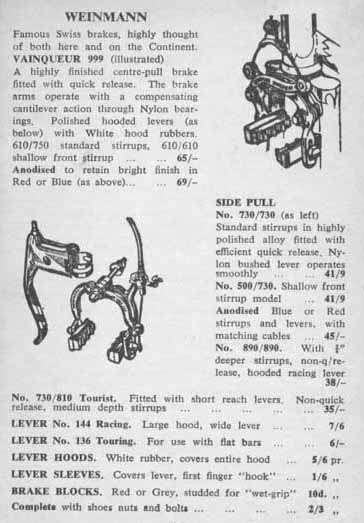

Side pull brakes: the 730 standard and the 500 for close clearances. These were made until their demise in the late 1980’s. These were, for over thirty years, the core product competitively priced. The 500 was always the cheapest option for equipping a close clearance frame, this design was extremely influencial for the major Far Eastern brake manufacturers. 730’s fitted to Dawes cycles in the 50’s and 60’s had the trade name Talon. There were longer reach versions the 810, 890 and 1020 originally for balloon tyred bikes. There was also a cheaper version for children’s bikes, the Junior. The 730 was also made in the 50’s under another model name, ‘Capella’ these are extremely rare.

Rims:

Wood insert sprint rims model Scherens weighing 11½oz

Hollow sprint rim the Criterium weighing 10 1/5 oz

High pressure rims, model name Alesa (box section) weighing 18oz

Endrick rims (weighing 22oz)

Rims were available in Britain 27 x 1¼”, 26 x 1 3/8″ and 26 x 1¼” and later, also 700c.

Alloy wing nuts: larger than normal with a circular cut out on the two wings, stamped Weinamnn. Also anodised blue and gold versions only made in the 1960’s

Weinmann were initially imported by Walter Flory, a Swiss national who also imported Lucifer, Lapize and Huret. He advertised regularly in the cycling press especially Sporting Cyclist. From the early 1960’s they were imported by Holdsworth and featured in the ‘Aids to Happy Cycling’ catalogues right up until 1981. After this date they were imported by R J Chicken until the 90’s.

Centre pull brakes were introduced in 1957 (the longer reach 750 and the shorter 610). The generic term for these was Vainqueur (victor) 999. They were first imported in Britain in 1959 (2). They were only used by racing cyclists in the first few years, Mafac and Universal were their major competitors. From the late 60’s most racers used side pulls, a change accelerated by the introduction of the Campagnolo sidepull in 1969. The 610 and 750 were popular amongst tourists.

They were fitted on all Dawes Galaxy’s (the most successful ‘off the peg’ tourer) until the mid 80’s when there was a move to cantilevers. Writing recently on the CTC website the CTC Technical Officer Chris Juden described them as the best of the old brakes and still very servicable.

OTHER PRODUCTS

The above components were the core Weinmann products. However they also made :

A dual pivot brake, the Dynamic, in the late 1960’s – similar to the better known GB dual pivot, the Synchron which was the result of joint venture between GB and Altenburger in the early 60’s. For some reason the Dynamic was not successful in the UK. These brakes it was claimed offered the advantages of the side pull (easy to set up) without the disadvantages (hard to centre) and were simpler than a centre pull i.e. did need the straddle cables and hangers. The bushing was made from delrin as were Mafac Racers from this date. In the 1980’s this was re- designed and became known as the Symmetric. Later in the 1980’s this was referred to by the initials PBS but by this time had become a very down market product.

Two piece handlebar stems (late 60’s to mid 70’s) the vertical part being steel, the extension alloy.

Alloy chainset and chainrings (five-pin). Not successful hence very rare.

Cantilever brakes. Two versions both made in the mid 80’s:

– A Mafac copy produced after Mafac went out of business around 1984; apparently they bought the Mafac tooling.

– a model aimed specifically at ATB usage.

Superior quality side-pull brakes:

– 605 with quick release on the stirrup

– Carrera a high priced Campagnolo copy in the mid 70’s. The top model.

– 400 black anodised close clearance

Polished alloy mudguards, stays fitted in French style. Also short ‘racer ‘ mudguards which were popular in the 70’s and fitted to many ‘sports’ racing bikes and needless to say offered no protection against the elements.

Brake tools: allen keys, brake clamp bolt spanner, inverse allen key, third hand brake tool.

Late 70’s concave rims. These were extremely strong but could lead to corrosion of the spoke nipples due to the shape of the rim retaining road salt.

Valve inserts: model Alligaro( 1950’s). According to Weinmann: “makes pumping almost a pleasure….”

The 730 and 500 in gold, red and blue anodised. These were stamped De Luxe.

Lever sleeves, white plastic which covered ¾’s of the lever blade. Hooked to improve finger grip.

The numeric model numbers refer to the reach in mm with another zero added usually the mid point. Thus 500 was between 42mm and 56mm .

MODEL CHANGES

Early versions of the centre pulls have arms with a difference curve .

Last version of these brakes have the name and model on a black background as opposed to the earlier red. There is a version of this brake with solid flat metal instead of a straddle cable (model 737) produced in the early 80’s.

Original versions of the side pulls have the name stamped in large letters on the brake arm without any border until late 60’s. The larger the lettering the earlier the brake.

Final versions of the side pulls have the forward centre bolt replaced with a black plastic reverse Allen key fitting (see picture of the Carrera). I think this was designed to make centring easier although to me it looks very cheap.

Earlier rims had a smooth surface later ones have a recessed channel running near the edge on either side.

Later rims are marked ‘Made in Belgium’ at some point production must have moved there. Indeed rims are still made to this day under the Alesa trademark (and very good touring rims they are too).

DATING

Some brakes have the month and year of manufacture on the rear of the arms eg 0576 = May 1976

Levers up to about 1964 have ‘Made in Switzerland stamped on one side of the upper lever blade (visible when lever is open).

Progressively the writing on the brake arms become smaller and finally is enclosed in a rectangle

Later products are stamped ‘Made in Belgium’.

PERCEPTIONS AND PERFORMANCE

Weinmann brakes and rims are not highly regarded by club cyclists or by VCC members. They rarely sell at cycle jumbles lacking the period appeal of GB or CLB or the stylish appeal of Mafac or Universal. I think this is because they were used widely in Britain as original equipment on many ‘starter’ cycles. In terms of performance my view is:

1. Rims are generally excellent, hard wearing and trouble free and liked by wheel builders. Although on some 1970’s high pressures the braking surface is very narrow.

2. Brakes.

I find the side pulls always seem to need centring but provide smooth and effective braking. The longer reach 810 and 890 suffer from flex due to the length of the arms and are best avoided.

Apart from the first generation, the centre pulls are too spongy for my liking and not surprisingly, as the marque enthusiast, I prefer Mafac.

3. Levers

I personally don’t find the levers comfortable. I think this is because the top of the blade by the pivot is flat not curved. I find cable replacement can be fiddly as the nipple tends to pop out of the lever end when you are setting them up.

A further problem is the lever pivots become loose due to wear there is no easy way to tighten them.

4. Lever hoods are hard wearing; maybe its just personal preference but I find the ribbed design uncomfortable.

With the move of manufacturing to Belgium (starting late 60’s but a gradual process) there was a definite drop in the quality of products.

DEMISE

After the mid 1960’s there was very little innovation, Weinmann essentially produced the core products of rim and brakes for the next 25 years. Their popular 1970’s “Safety Levers” (an extra arm from the lever running parallel with the flat of the drop bar) were in fact a Dia Compe patent licensed by Weinmann. I am of the view that the presence of these levers automatically relegates a bike to low price/quality. They provide a benchmark for spongy braking and worsen the performance of the main lever. The fact they became a requirement for bikes imported into the USA shows just how little cycle braking is understood by non cyclists.

In the 1980’s they relied increasingly on licensing products from Dia Compe who at that time were the largest volume brake producer in the world. Thus Weinmann Aero brakes are in fact badged Dia Compe product. Surprisingly Weinmann first worked with this Japanese firm as far back as 1963 on technical development.

Weinmann ceased trading in the early 90’s. Like many other companies they failed to make the transition to mountain bikes. Mavic cornered the rims market and Shimano moved into brakes. Alesa still survives as a maker of rims based in Belgium and seem to be linked to Rigida formerly a French manufacturer. See news on Weinmann – USA at bottom of page.

| MODEL | MINIMUM (mm) | MAXIMUM (mm) |

| 400 | 40 | 54 |

| 500 | 43 | 56 |

| 730 | 56 | 75 |

| 810 | 60 | 79 |

| 890 | 68 | 85 |

| 605 and Carrera | 45 | 58 |

| 610 centre-pull | 50 | 65 |

| 750 and 737 centre-pulls | 53 | 80 |

| Dynamic model 712 | 54 | 68 |

| Dynamic model 812 | 62 | 79 |

REFERENCES

1. Cycling 25th August 1949 p213 ref to the importing of Lucifer, Huret and Weinmann by Walter Flory

2. Sporting Cyclist Jan 1959

SOURCES

Holdsworth Aids to Happy Cycling from 1958 to 1981 and late 50’s early 60’s Sporting Cyclists

Walter Flory’s advertisements in Sporting Cyclist 1956 to 1963

My thanks to Hansjurg Albrecht, a Swiss VCC member, for first hand information and Ray Miller for information from the VCC library

Raleigh had special versions of Weinmann brakes made for some years. For example Carltons with CP brakes would come with (almost indestructible) hard plastic lever hoods with ‘Carlton’ branding on the sides. These were available in black or white in the 1970s. I have no idea how they got the hoods on or off the lever body; they don’t stretch at all. The matching calipers often had ‘Raleigh’ on the inset label, instead of ‘Vainqueur’.

Weinmann 500 side pull brakes were for some years the lightest-weight standard brakeset available; these calipers found use on many time-trialling machines as a consequence. Usually the finish was polished, but coloured anodised finishes were also available. Weinmann took low weight very seriously; brake shoes were made of aluminium, and were often fitted with aluminium mounting hardware, e.g. aluminium domed nuts on brake shoes and the brake centrebolt. Barrel adjusters were often made from aluminium, and when threaded into brass or steel fittings they would often corrode in winter conditions.

Weinmann side pull brakes were designed so that the barrel adjuster and the pinch bolt could be exchanged for one another, allowing a bottom entry cable mounting (for a ladies or mixte frame) onto a standard caliper. For a time Dawes fitted these brakes with a rubber ‘bellows’ cover piece which was intended to deter water from entering the cable housing on such machines. The sidepulls are sometimes fitted with a QR lever in the barrel adjuster fitting. Another optional fitting was a ‘speed adjuster’ where the barrel adjuster is fitted with a toothed wheel which can then be turned about x2 faster than normal by turning a larger plastic knob which meshes with it.

In the late ’70s or early 1980s the domed centrebolt on the standard side-pull calipers was replaced by a plastic cover over two plain steel locknuts. These brakes were centred using an inverted allen key tool. At the same time the grooved spring retainer on the centrebolt was also changed for a plastic part. In the 1980s the arms themselves were redesigned to a smoother profile, with less clearance for wide mudguards and no inset panel for the model identity. All these brakes were supplied in a polished finish, with printed logos on the brake arms.

Although the 1961 advertisement in the main article above mentions the ‘centreing nub’ which synchronises the centre-pull brake arms, and these brakes had only been in production for a few years, it seems there was an alternate (earlier?) version of the centre-pull brake. This is superficially similar to the more familiar version, but lacks the centreing nub. It also has pivot bolts with 11mm heads rather than 10mm heads, and other detailed differences, such as pivot bosses riveted into the yoke, no date stamp etc. I have a set of these brakes, and I don’t think I’ve ever seen another identical set.

The Weinmann brake lever came in two basic versions; the standard lever pivoted on large bushings set in the middle of a wrought lever hood. The alternative ‘Carrera’ lever (supplied with the 405, 605, Carrera models of SP brakeset) instead used a lever pivot set forwards and lower in a cast lever hood. These levers are almost identical in shape, working geometry and feel etc to the classic Campagnolo Nuovo Record models, and will even accept Campag rubber lever hoods. These levers were available in both smooth and perforated versions.

The basic lever was over the years fitted with several different styles of lever blade. Variations include to the Weinmann logo, the lever shape, a side hole to accept the ‘safety lever’ fitting, the lever texture, a QR button and lever perforations. There are also small variations to the fitting which accepts the cable nipple. Probably there are in total over a dozen different versions. Some time in the 1980s the shape of the lever hood itself changed slightly, so that the lower front portion of the hood was angled instead of square.

The centre-pull brakes were available with many slight variations to the fittings which allowed fitment to different frames. For example there was an optional ‘long straddle’ which allowed fitment to mixte frames, as well as numerous variations to the design of the cable hangers.

Overall, I have found these brakes to be lightweight and (provided the reach is not too long..) reasonably functional. Strangely (for a well made lightweight Swiss product) I don’t expect them ever to become coveted items in the UK, because of their near-ubiquity.

Bruce Dance also adds some photos of early model Weinmann Vainqueur 999 model calipers, which are in the same-(ish ) lengths as the later models but are made differently and lack the self-centring mechanism.

The bosses are riveted onto the backplate and protrude 6mm @12mm dia and a further 10mm @ 8mm diameter. [NB possibly this means the arms also fit to Mafac bosses; I have not checked.] There are no bushings in the pivots; the aluminium arm bears directly onto the boss.

The backplate is marked “BRAKE MADE IN SWITZERLAND BY WEINMANN” both sides of the centre bolt and each arm is marked with the length (610 or 750) and a further two digits which I believe to be a date mark; in this case ’63’ which I think means 1963.

The bosses are tapped M6x1 to about 12mm depth and the bolts have 11mm hexagons on them. The brake reach measures 42-62mm for the ‘610’ model and 52-76mm for the ‘750’ model. Both brakes have anodised aluminium decals (similar to the later models I think) that read “vainqueur/999” that sit in shallow slots that (by coincidence or otherwise) almost exactly mirror the position of the centring mechanism in later brakes.

Perhaps I have not been paying full attention but this is the only set of these brakes I have ever seen. I think they came to me attached to a very broken early 1960’s claud butler, which may have had a 531 fork but was otherwise unremarkable.

Sam Lingo from the States gives some extra details relating to Weinmann in the USA, Sam has some Mexico-manufactured Weinmann rims.

January 1, 1970 – Karl Heinz and Erika Schaette incorporate their new company KHS Bicycle Parts. KHS Bicycle Parts represents several European companies. The main focus are the products from Union Froendenberg, Weinmann, SKS, ESGE, Reich,and Eldi. An office is established in New York City and three years later in Houston Texas.

1975: To offset the high cost of transportion Karl convinces Union Froendenberg and later Weinman to open a manufacturing plant in the US. Olney is chosen due to the central location. KHS moves office to Olney. Weinmann follows suit and also opens manufacturing plant in Olney. KHS moves to Olney in 1979 after the production of the two companies starts.

Weinmann Closes Illinois Factory. Publication: Bicycle Retailer Date: Friday, May 24 2002

OLNEY, IL (BRAIN)–Weinmann closed its rim factory in Olney, Illinois, and shifted all Western hemisphere production to its plant in San Luis Potosi, Mexico. Also, Alesa, its European parent company, declared bankruptcy. Alesa is owned by the Rigida Group.

“Weinmann Inc. isn’t itself in Chapter 11–it isn’t in bankruptcy. It has sold its [U.S.] real estate, it’s winding down its business and it will exit the rim-making business in the United States because the market has disappeared,” said Kevin Duffy, Weinmann USA’s president.

Posted: Friday 12th June 2020

Contents

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.