Success Cycles

Posted: Monday 08th June 2020

The Success Cycle Manufacturing Company was based at 43 London Street, Chertsey and in 1948 introduced a radical new frame design known as The Success – dual-line bicycle frame. They produced three solo frames, Models 1, 2, and 3 plus Model 4 – a tandem.

Model 1 – Twin tubes ½” diameter Grade A steel; Head and Seat tubes Grade A steel; Forks – Russ pattern, cast crown cut with frame pattern; Steering fittings – Standard; Finished in coloured enamel, no plating. £10 5s 9d

Model 2 – Twin tubes in Chrome Molybdenum steel; Head and Seat tubes 531 or Chrome Molybdenum; Forks – Tin blade or Russ pattern, pressed crown cut with pattern of frame; Finish – Any colour enamel, plated ends to 6″ front and rear plus plated crown. £11 10s 6d

Model 3 – all tubing Chrome Molybdenum or 531; Forks – Continental, twin or single blades oval or round; Steering fittings – Continental; Finish – any colour enamel, plated crown and fork ends to 6 ins. £12 5s 6d

Model 4 – TANDEM. Similar construction – double gents. £18 18s 0d

The frames were offered in all-chrome or Super Electro-Flamboyant finish for extra cost; another extra was a brazed-on lamp bracket socket with chrome lamp bracket.

The seat tube, head tube and forks were conventional but the top tube/seat stays/chain stays and down tube were fabricated from continuous ½” diameter twin tube loops which were brazed on either side of the seat and head tubes.

Like many such ideas the concept was not accepted amongst serious cyclists and only about 25 or so were built, which was not enough to make the company viable so it went into liquidation after a few years.

The ‘Yarmouth Mercury’ in 1948 printed the following:

“An unorthodox type of frame is used in the experimental cycle which has been designed and built by Mr. G.A. Cushing, a Gorleston cycle repairer. Instead of the usual triangulated frame of straight tubes he uses a pair of narrow tubes which run parallel to each other from the back axle to the pedal bracket, then curve in a flattened “S” shape up to the steering column before bending back in a curve to the seat pillar and down to the back axle again.

The advantages Mr. Cushing claims for the design are that it is lighter than the ordnary frame, yet rigid, and that the kink in the tubes at the front lends a springiness which absorbs shocks and makes for easier riding. The model is soon to be tried out over a 25 mile course by a member of the Wheelers.” Another advantage is the ease with which one can change the head and seat angles to suit any requirement without the need for lugs of course.

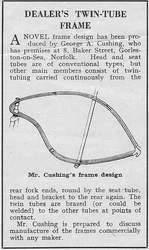

An advert in the Motor Cycle and Cycle trader (see image above) also in 1948 also gives George A Cushing as the producer and goes on to say that Mr Cushing is prepared to discuss manufacture of the frames commercially with any maker. The brochure for the frame is in the name of: The Success Cycle Manufacturing Company of 43 London Street, Chertsey who we can assume took up the offer.

The first 1948 model was probably a prototype and there are reports of it being ridden in time-trials in Norfolk.

The frame design was granted a Patent No 639.709 for ‘Improvements in or relating to Bicycle frames’

The application was made on 25 November, 1948 in the name of George Anderson Cushing of 8 Baker Street, Gorleston-on-Sea, Norfolk.

If anyone has further information of this make, or even better, who owns one, please get in touch – details on the Introduction Page

Posted: Monday 08th June 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.