Chater-Lea

Posted: Sunday 13th September 2020

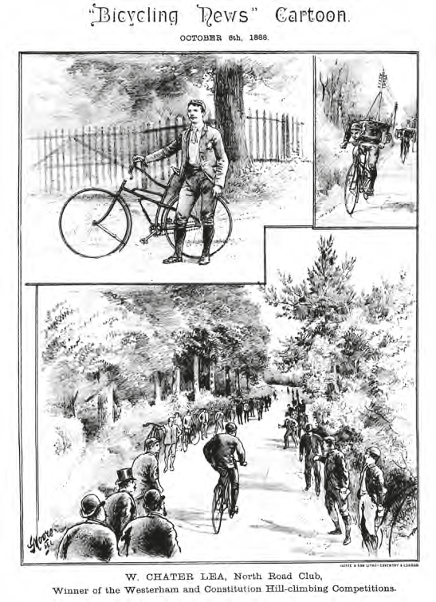

Chater-Lea was founded by William Chater Lea in 1890. The now well known hyphenated name was adopted by the company some 30-years after founding in the mid-1920s for aesthetic reasons.

William Chater Lea (born 1859) acquired his early engineering skills while an apprentice at Linley and Biggs, producer of the legendary Whippet. Grace’s Guide, a website dedicated to British industrial history, describes the Whippet as a “machine that embodied the most practical and successful spring-frame ever designed, it’s great feature being that the relative positions of the saddle, pedals, and handlebar, did not vary, these three points being built on a rigid triangle, separated from the main frame by a strong coil spring and a movable shackle in the steering mechanism. Thus it was impossible for road shocks, from either wheel, to reach the rider.”

William rode the Whippet in races with much success, winning the The Catford Hill Climb the world’s oldest (and at the time most prestigious) bike race in 1888, 1889 and 1891. He chose not to ride in 1890 the year he founded the company.

Chater Lea was a talented engineer, inventor and designer securing several early patents. He founded the company with a clear vision and focused two essential principles, peerless quality and continuous invention.

From its origins as a maker of bicycle frames and components, by the turn of the century they were makers of motorcycles and shortly thereafter cars. However, it was their prowess as makers of the components for which they were most widely recognized and where they established a global reputation as the finest component maker of the era. With the rapid growth of the company they were required to move on several occasions to larger premises. Between 1890 and 1911 they occupied several factories in East London including: Richmond Street, Great Sutton Street and Golden Lane.

In 1911 they moved into a large purpose built factory at 74-84 Banner Street in Clerkenwell London, EC1. The nine-story building was one of the few buildings in the area to survive the blitz unscathed and can still be seen today with its entranceway still displaying the Chater-Lea sign.

By the mid-1920s they had outgrown the Banner Street site and commissioned a large new purpose-built factory in Letchworth Garden City. As one of the world’s first new towns and the first garden city the town had great influence on future town planning and the New towns movement. Unfortunately, William died in 1927 just months before the company relocated to the new factory on New Icknield Way, Letchworth. The period from the opening of the new factory until the start of WWII is seen as the companies golden age when they were both exporting their products globally and manufacturing the very finest bicycle components available.

Upon his death the firm was taken over by his two sons John and Bernard who ran the company along with other family members until the firms eventual demise in the late 1980s.

From its founding Chater-Lea engaged in continuous invention and innovation in manufacturing. During the first year in business the firm patented an ingenious chain-protecting cover. This consisted of an endless rubber band, U-shaped, and reinforced by a canvas insertion. This enclosed the outer surface of the chain, rotated with it, and utilized a dry lubricant which did not perish the rubber. About a year later the company launched a new light mudguard that could be rolled up like a blind.

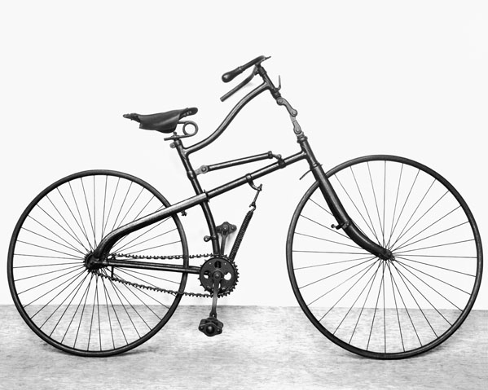

However, the company’s core business was the production of manufactured fittings and component parts. It did produce a popular double top tube frame from 1895 as well as several other models of complete bicycles and tandems. Wanting to focus on their core business of components the company transitioned orders for bicycles to the Raleigh Cycle Company and tandems to F. H. Scott. At this time there were a number of cross-licensing agreements with other makers including F Bowden of Raleigh for a cross-frame which was made by Raglan Cycle Co. Ltd of Chater-Lea materials and fitted with Chater-Lea components.

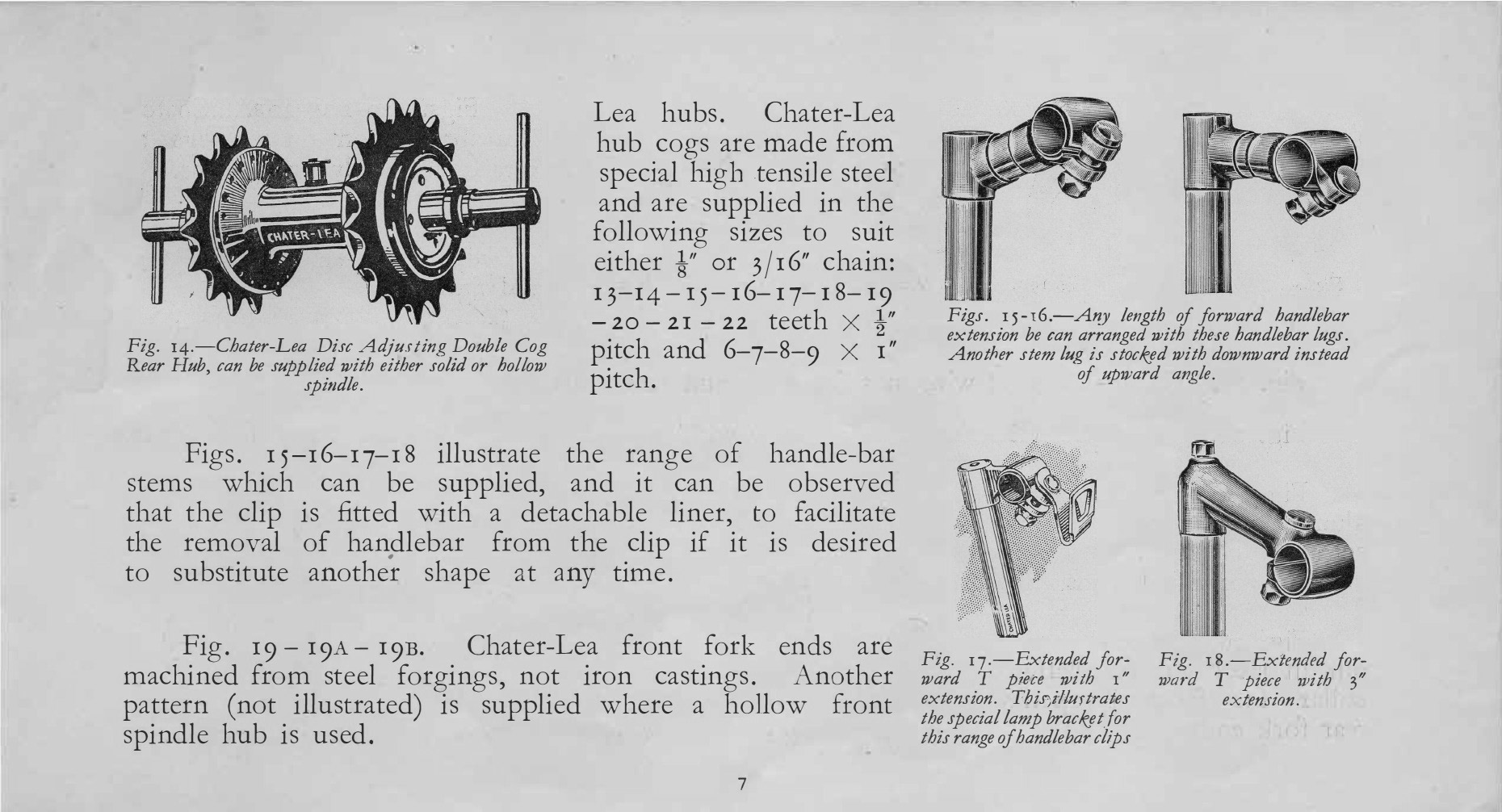

A review of the beautifully produced annual catalogues from the era show the breadth of products produced by the company from the turn of the twentieth century onwards. From early in their history they had an extensive global distribution network, in particular across the commonwealth. From Durban South Africa to Auckland New Zealand there were local importers and distributors of Chater-Lea bicycle products (as well as its motorcycles).

Customer service and ultimate satisfaction were the watch-words for the company and all those who worked within it. This was particularly well articulated in a confident tone in their 1928 Cycles and Tandems Catalogue, a page from which can be seen below.

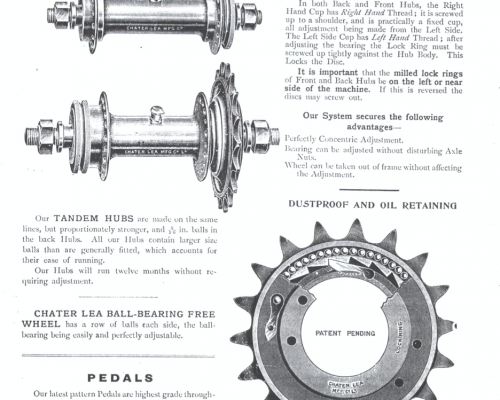

As producers of fittings and components the company was capable of meeting the needs of its own bicycle business as well as supplying the leading custom builders and larger manufacturing companies. Frame building materials including tubing and lugs were considered the very finest. Alongside these items cranksets including arms and rings, pedals, hubs and headsets were the mainstay of the business. Its renowned selection of handlebars were considered the most diverse and well built available.

The other point is two arm or three arm Chater-Lea cranks ? The answer is that Chater-Lea made their cranks in both forms from the turn of the last century

– attached are a couple of photos of three arm types. The first (previous page) is a 7H in forged crank from 1912 and the second (right) shows a 1951 post-war, square crank made in two separate parts which were copper brazed together. This latter crank was produced in three lengths (6H in, 6I in and 7in) in both two arm and three arm form. The post-war round crank only came with three arms and the one length of 6H in.

One last point, if members have a stripped bolt thread on their Chater-Lea cranks there is a neat repair. I make ‘repair’ bolts to match in metric M7 x 1 mm, so the damaged thread can easily be tapped out (M7 x1 mm is pretty well the same pitch as 25 TPI Whitworth) and the bolt replaced with one that does not offend visually.

In the era when cranks were still attached to bottom brackets by cotter pins, Chater-Lea made gorgeously polished steel cranks and, later, highly distinctive large-flange hubs with large round lightening holes in the flanges.

Above you can see a three-arm fluted Chater-Lea chainset fitted with an inch-pitch chainwheel and block chain. Also above, one of the early two-arm Chater-Lea fluted chainsets fitted with the very rare Chater-Lea double chainset. On these cranks the third bolt is into the back of the crank. This conversion is achieved with a Chater alloy spacer, two rings and longer bolts.

The alloy spacer is manufactured in two thicknesses, used here is the thinner for a 3/32 double conversion. The thicker version was for use on tandem drive.

Sometimes the outer ring has to have the inner flange removed to allow the chain to lift from the inner ring.

For a period Chater-Lea produced these very fine round cranks, shown here with Chater-Lea pedals. The round cranks were introduced at the London Cycle Show in 1948. They were not as strong as the fluted cranks and so were not suitable for sprinting on the track. 50s riders do claim that they were prone to breakage but we have neither seen nor heard stories of failures during competitive use.

The first image in the gallery below is one of the little treasures found in Bernard Chater-Lea’s works desk. From 1925, it’s a very rare Chater-Lea disc adjusting hub with a splined fixed sprocket and circlip – the only one I’ve ever seen. So nice to see also is the original Chater-Lea oiler and cap – these very rarely survive with the cap intact. The sprocket is so easy to remove and replace. Eat your heart out Sturmey-Archer!

The second image are of the very rare pre/post-war Chater-Lea small-flange front hubs. These hubs had a hollow axle and were fitted with a grease nipple on the end. (just visible on to hub left end) Grease pumped through the nipple would emerge inside the barrel via a hole in the axle. Image by Peter Brown.

The third image is another rare sighting. A pair of Chater-Lea large flange hubs, this time the grease nipples at the end of the axles are easily seen. On rare occasions these hubs were prone to the spokes cracking the flanges and it can be seen that the drillings are very close to the rim. Image by Peter Brown.

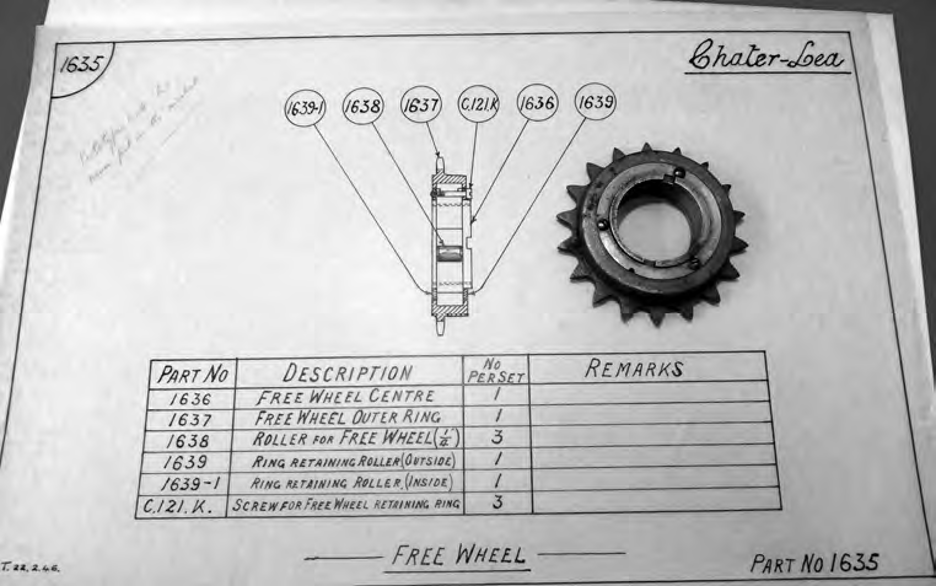

Another little bit of history from Bernard Chater-Lea’s desk. In 1946 Chater-Lea designed a freewheel which ran using three rollers instead of the usual pawls and springs. Only the prototype was made and it never reached the market. Below are photographs and one of the original works drawings with Bernard Chater-Lea’s pencil notes on the top left corner. Courtesy: Chris Grange & VCC

Chater-Lea Today

In 2017 the revival of this iconic cycling marque began. A small team of passionate individuals have made it their mission to bring Chater-Lea back to the forefront of bicycle component manufacturing and have introduced the first new components in over 50-years.

The passion for the history of British bespoke bicycle manufacturing ultimately led the company to cross paths with the founder (and curator) of Classic Lightweights (Peter Underwood). During our many conversations it became apparent that the Classic Lightweights website needed to be updated and its long time future secured. In early 2020 the team behind the revival of Chater-Lea took over the day-to-day management of the site and are committed to ensuring its ongoing availability as a free, non-commercial resource the cycling community and others interested in the history of UK manufacturing.

Posted: Sunday 13th September 2020

This article appears in the following categories.

Upcoming Events

Whether you are looking for a gentle social meet up, or a 100-mile ride browse the community’s upcoming events and plan your next weekend outing.